How to ensure steam supplied to the process is clean

Debris can occur in steam systems due to a number of reasons e.g. rust due to corrosion of the metal surfaces like pipes and valves, scale due to poor water quality or carryover from the boiler and foreign debris introduced to the system during maintenance / repair like welding slag, dirt, etc. It can cause wear and tear and damage sensitive equipment like PRVs and isolation valves, block lines and accessories leading to unsafe conditions and compromise the quality of steam used.

Strainers should be installed in the steam distribution network, especially upstream of critical accessories like steam traps, control valves and flow meters, to separate and remove debris and maintain the quality of steam.

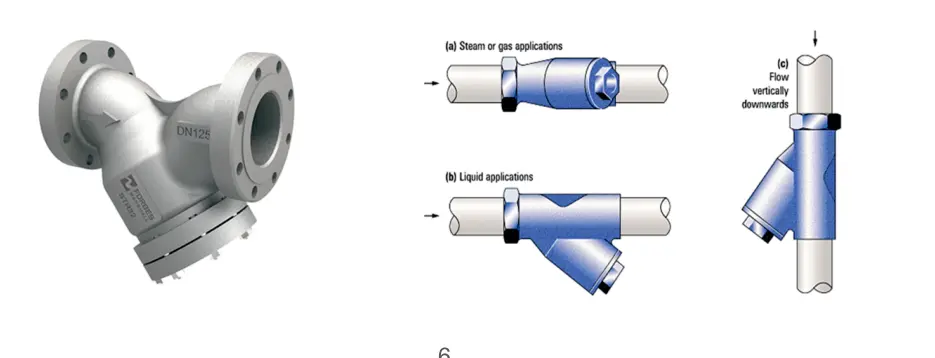

Y type strainers are typically used in steam systems and care should be taken during installation as incorrect installation can lead to accumulation of condensate and wet steam. On steam lines, strainers should always be installed with their strainer screen baskets on the side.

Illustration: How to install strainers