Conventional Steam Pipeline Trapping Station vs. Advanced Mainline Steam Trapping Solution

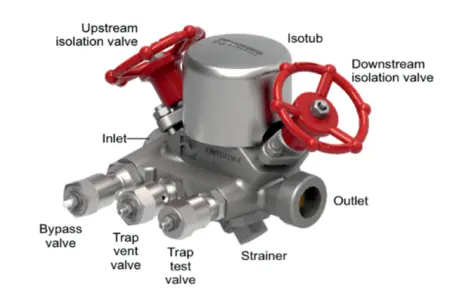

State-of-the-art thermodynamic steam traps encompass the complete steam trap module in one single forged body. These solutions are easy to install, operate and maintain and offers several advantages over a conventional steam trapping station.

Table : Comparison of conventional steam pipeline trapping station against an advanced mainline steam trapping solution

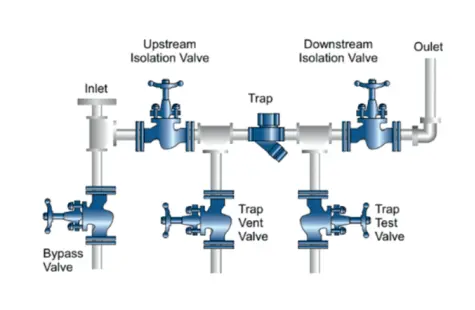

| Conventional Steam Trapping Station | Advanced Mainline Steam Trapping Solution |

|---|---|

|  |

| Approx. 750mm assembly length and weighing over 14 kgs | Compact and lightweight – 190mm assembly length and weighing about 6kgs |

| Has 16 components with 5 valves requiring on-site fabrication and welding (15 weld joints); ~ 4 hours to install and commission | Only one component with 5 integral piston valves; installation time of ~30 minutes |

| Shutdown / safe isolation not possible, hampering online / in-line maintenance as traditional valves are prone to leakages and seizing up | Integral class VI bypass and isolation valves enable safe isolation for easy and safe online/ in-line maintenance |

| Trap needs to be replaced in case of damage to the seat | Replaceable seat and disc |

| Intermittent, noisy and scattered discharge of hot condensate causing erosion of surface onto which the condensate is discharged | Inbuilt diffuser enables reduction in noise level and gentle discharge of condensate for open to atmosphere applications thus ensuring safety |

| Cumbersome to maintain due to welded joints | Quick and easy to maintain |

| Potential steam leaks through inline leakages, glands and weld joints | Zero leakage |