Calculating losses from steam traps

UNFCCC classification and loss computation based on working status

As per the United Nations Framework Convention on Climate Change (UNFCCC) steam traps can be classified as follows based on their working status.

Table: UNFCCC Steam trap classification based on working status

| Terminology | Description | Definition |

|---|---|---|

| OK | Good Trap | Trap in normal operating mode |

| BT | Blow through | Trap has failed in an open mode with maximum steam loss |

| LK | Leaking | Trap has failed in a partially open mode with a steam loss of approximately 25% of maximum |

| RC | Rapid cycling | Disc trap going into failure mode |

| PL | Plugged | Trap has failed in a closed position and is backing up condensate |

| FL | Flooded | Trap is assumed to be undersized and unable to handle the condensate load |

| OS | Out of service | The steam supply line is off and the trap is not in service |

| NT | Not tested | Trap in service but not tested due to inaccessibility |

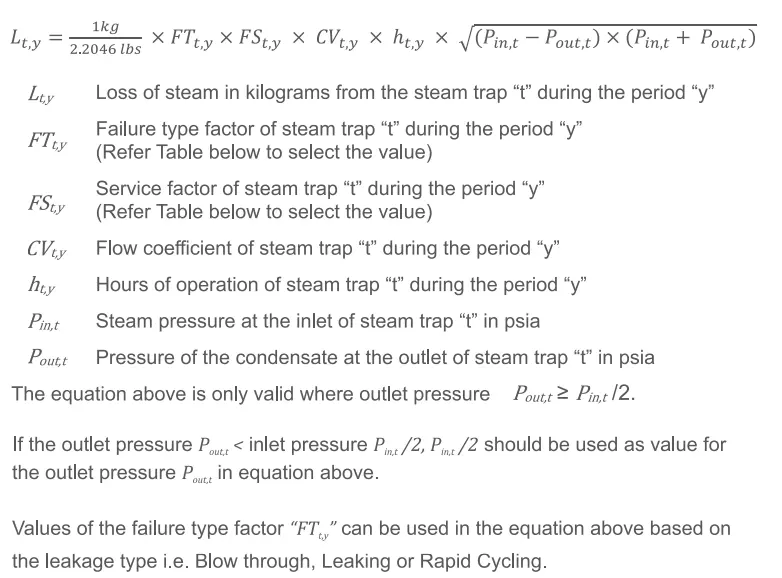

Computing steam loss through leaking steam traps

The United Nations Framework Convention on Climate Change (UNFCCC) has defined a methodology to compute the loss through leaking traps.

| Type of failure | FT ty |

|---|---|

| Blow-thru (BT) | 1 |

| Leaking (LK) | 0.25 |

| Rapid cycling (RC) | 0.2 |

The service factor “FT ty” takes into account that the steam loss depends on the trap size (orifice) in relation to the actual load, which differs based on applications. This value can be determined from the table below

| Application | Service Factor FS ty |

|---|---|

| Process steam traps | 0.9 |

| Mainline and tracer steam traps | 1.4 |

Steam losses also depend on the actual size of the orifice. The flow coefficient “CV t,y.” is a function of the orifice size (in inches).

CVt,y= 22.1 × D²

Where D² is the diameter of the orifice in inches