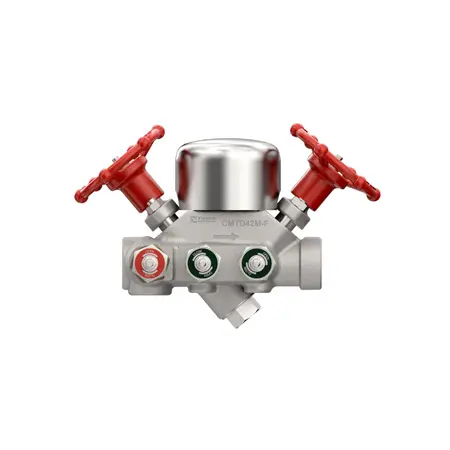

Compact Module Thermodynamic Steam Trap CMTD™

If steam traps are not installed, operated and maintained properly, their efficiency can degrade. The Forbes Marshall compact module is formed by connecting the universal connector thermodynamic steam trap to a pipeline connector. As the name suggests, the module is compact thereby offering ease of installation and operation.

Forbes Marshall offers a wide range of CMTDs which come with isolation and bypass provisions to facilitate ease of maintenance. The compact modules are also installed quickly compared to conventional trap assemblies.

Read how CMTD compares with conventional mainline steam trapping stations

- Modular design brings down the number of welds required for installation to 2, resulting in fast installation in just 45 minutes.

- Single permanent in-line component for ease of specification and installation.

- Forged carbon steel construction for long life.

Variants

- CMTD42M-S, is a compact

- thermodynamic trap module

- designed with an in-built upstream

CMTD42M-F, is a compact thermodynamic trap module designed with an in built bypass valve, a trap vent valve and a trap test valve for steam applications upto 42 bar g @425 Deg C.The CMTD42M-F has an integral upstream and downstream piston valve, which isolates the upstream piping of the steam trap.

CMTD62M-S, is a compact thermodynamic trap module designed with an in built upstream isolation valve and bypass valve for steam applications upto 62.5 bar g @482 Deg C

TMO -525 deg C@42.7 barg

CMTD62M-F, is a compact thermodynamic trap module designed with an in built bypass valve, a trap vent valve and a trap test valve for steam applications upto 62.5 bar g @482 Deg C. Replaceable trap internals and inbuilt strainer eases inline maintenance. The CMTD42M-F has an integral upstream and downstream piston valve, which isolates the upstream piping of the steam trap.

TMO -525 deg C@42.7 barg

CMTD250M, is a compact thermodynamic trap module designed with an in built isolation valve, bypass valve, a trap vent valve and a trap test valve for very high pressure steam applications upto 220 bar @374 deg C.

TMO -550 deg C@80 barg

Frequently Asked Questions

Advanced mainline solutions, like the Forbes Marshall Compact Module Thermodynamic Trap combine multiple components, such as separators and strainers, into a single unit, ensuring efficient steam trapping. This easy to install and maintain solution is the ideal alternative to conventional stations.

A modular mainline steam trapping solution offers flexibility, scalability, and ease of installation in large steam systems. Integrating the trap components, helps simplify maintenance, and allows for easy upgrades or replacements.

Advanced solutions like the FMCMTD reduce maintenance frequency and costs by offering better durability, easy inspection ports, and streamlined servicing processes, with no system downtime.

The trap operates by automatically discharging condensate when steam pressure exceeds a set point, ensuring minimal steam wastage and consistent performance.

Forbes Marshall Care

Forbes Marshall Care Forbes Marshall Surveys

Forbes Marshall Surveys Strainers FMSTR

Strainers FMSTR Bimetallic Thermostatic Steam Trap FMBM

Bimetallic Thermostatic Steam Trap FMBM Forbes Marshall Air Eliminator FMAE

Forbes Marshall Air Eliminator FMAE Air Vents for Steam Systems FMAV

Air Vents for Steam Systems FMAV Forbes Marshall Diffuser DIFF

Forbes Marshall Diffuser DIFF Insulation Jackets IJ

Insulation Jackets IJ Forbes Marshall Vacuum Breaker FMVB

Forbes Marshall Vacuum Breaker FMVB Steam Moisture Separator FMSEP

Steam Moisture Separator FMSEP