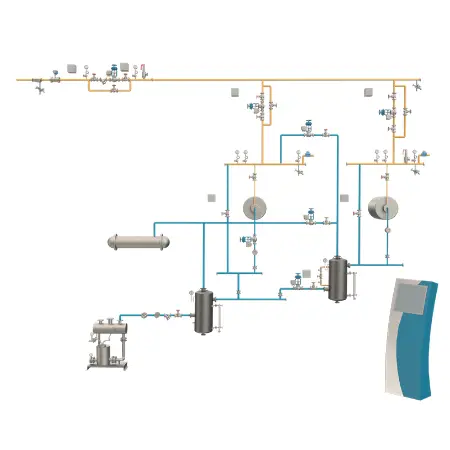

Cascade Based Paper Drying System

The Forbes Marshall cascade based paper drying system is ideal for use in cases where available pressure is between 3.5 to 4.5 barg, or in cases where turbines are present.

In this system, fresh steam is supplied to the different dryer groups, and pressure is controlled individually for each group. This steam partially condensates in the drying cylinder and the energy is transferred to the paper via the drying cylinder shell. Blow through steam and condensate are removed from the drying cylinder into condensate tanks and passed on to lower pressure groups. The condensate is collected into the main condensate tank and pumped back to the boiler feed water tank.

- Pressure, differential pressure and level control loops

- Auto set point prediction for pressure

- System efficiency monitoring with real-time SSC, CRF and productivity

- Real time data logging and comparisons with industrial bench marks Remote connectivity

Have a project in mind that you think we’d be a great fit for it? We’d love to know what you’re thinking