Maximising energy efficiency is of prime concern across industry. Forbes Marshall’s metering and efficiency monitoring solutions together with our control systems and heat recovery units help you keep track of critical parameters and recover every bit of energy that might be lost in the boilerhouse itself.

Boiler efficiency is not constant. Large variations take place during the course of operation. Surveys indicate that unmonitored boilers often operate 5%-15% below their rated efficiency, directly affecting fuel costs. Over time, these fuel expenses exceed the initial cost of the boiler several times over.

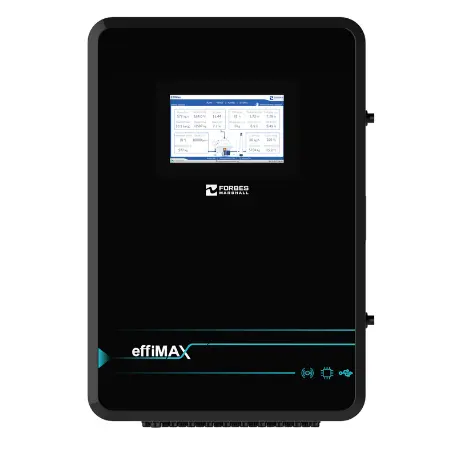

Real time monitoring can help significantly improve boiler efficiency, depending upon the boiler type and actual conditions at site. Forbes Marshall’s boiler efficiency monitoring systems are designed to ensure optimal performance. They are equipped with sophisticated automation and control technologies to continuously monitor and provide real time analysis of critical parameters such as fuel consumption, steam production, flue gas composition, and temperature. This not only ensures peak boiler performance but also minimises fuel costs and environmental impact by reducing emissions.