Tyre and Rubber

Driving Productivity and Sustainability. Achieving Operational Excellence.

Whether optimising an existing facility, planning an expansion, or launching a greenfield project, our engineered solutions and services enhance steam management, optimise energy consumption, improve operational performance, reduce water usage, enabling steel plants to achieve efficient and sustainable production..

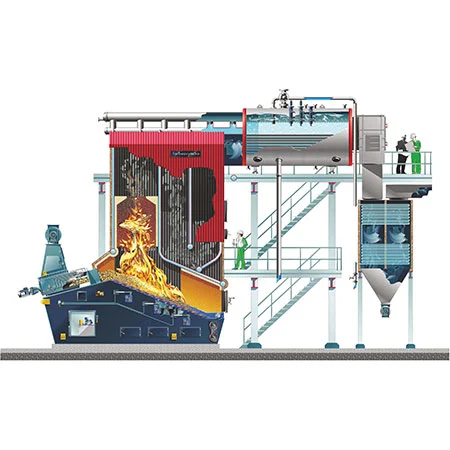

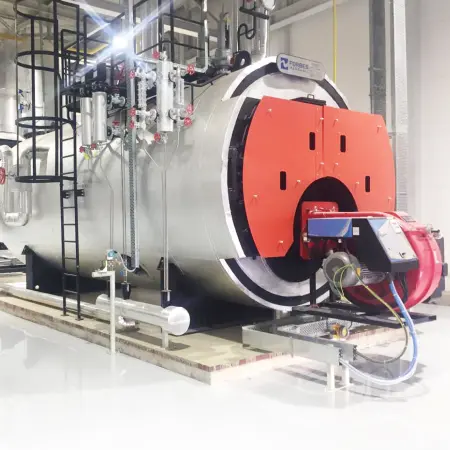

| Steam plays a vital role in various processes, such as curing, heating, and drying in the rubber and tyre industry. Improper steam management can lead to energy wastage, equipment downtime, and high operational expenses. Many plants encounter challenges like water hammer, inefficient condensate recovery, and excessive steam losses, negatively impacting productivity and quality. Backed by decades of expertise in steam and condensate management, Forbes Marshall understands the challenges faced. We offer tailored solutions to help plants streamline their production processes, reduce waste, and boost productivity. Our range of offerings include advanced steam traps, condensate and flash steam recovery systems. We also enable plants to lower emissions, conserve water, and adopt more sustainable practices. With our comprehensive range of products, services, expert technical support, and commitment to innovation, we empower the tyre and rubber industry to achieve operational excellence, improved product quality, and operate sustainably. |

Let us help you

Water and Wastewater

Explore our solutions for the chemical and API industry.

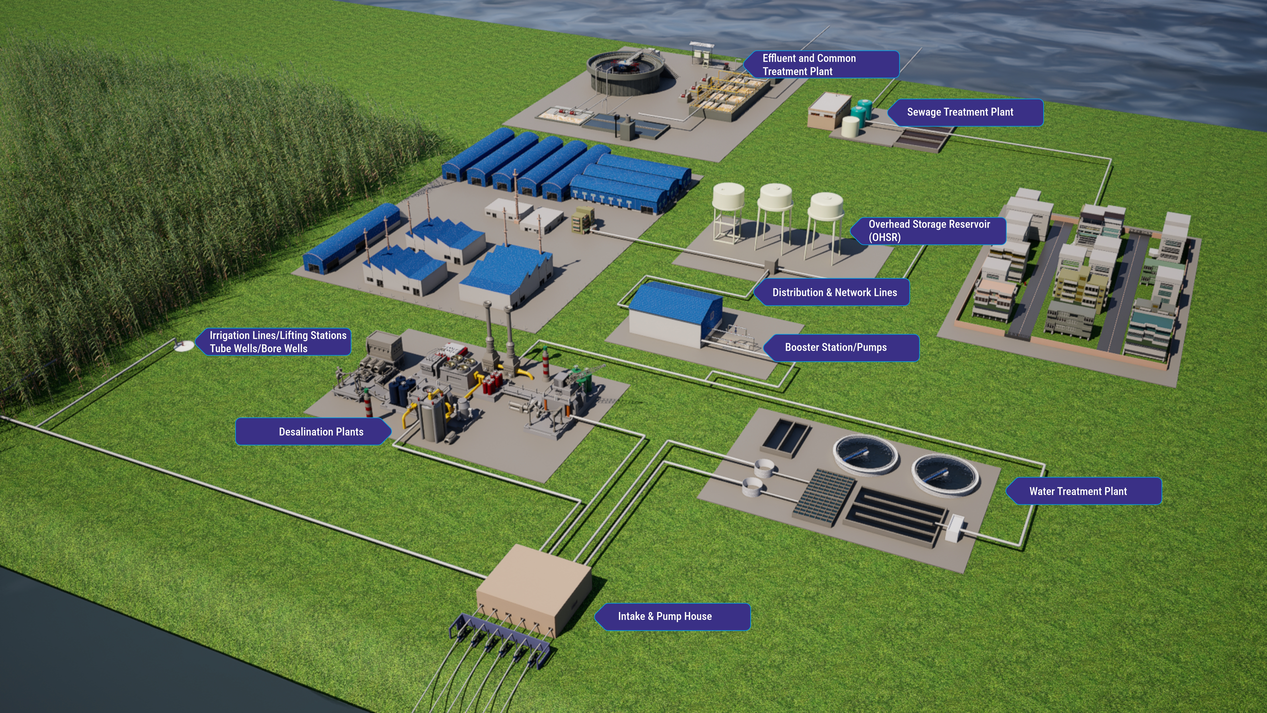

Effluent and Common Treatment Plant

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Sewage Treatment Plant

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Overhead Storage Reservoir (OHSR)

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Distribution & Network Lines

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Booster Station/Pumps

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Water Treatment Plant

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Intake & Pump House

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Desalination Plants

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Irrigation Lines / Lifting Stations Tube Wells / Bore Wells

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,