Textiles

Streamlining Efficiency and Sustainability

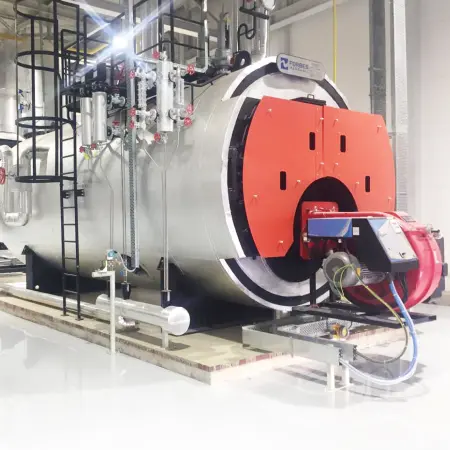

Whether addressing an existing facility, planning an expansion, or launching a greenfield project, our engineered solutions and services optimise steam usage, enhance process efficiency, reduce water consumption, and minimise the impact on environment, delivering sustainable outcomes for the textile industry.

The textile industry encompasses diverse sub-sectors such as weaving, knitting, denim production, dyeing and garment manufacturing. However, textile manufacturers face several key challenges, including managing energy consumption, optimising processes, and reducing costs, all while ensuring sustainability.

Inefficient steam usage not only drives up energy consumption, but also increases operational costs and hampers productivity. Problems like excessive blowdown, steam trap leakage, condensate wastage, and low feedwater temperature contribute to higher fuel bills and water usage. Additionally, issues such as steam starvation, poor steam quality, and contamination during the dyeing process lead to production inefficiencies, compromised product quality, and frequent rejections, all of which affect profitability.

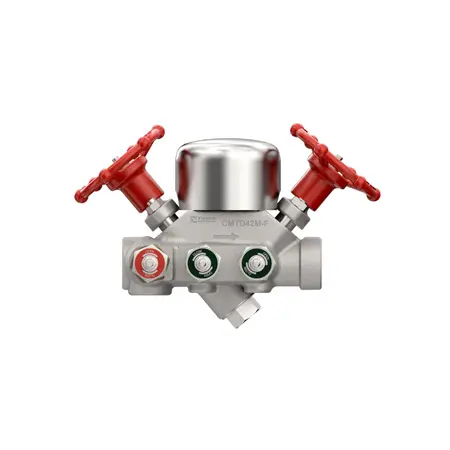

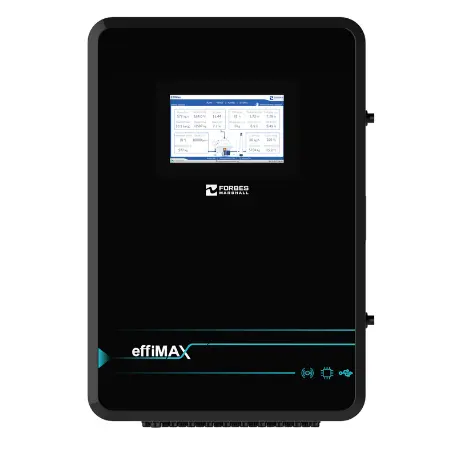

Forbes Marshall offers a range of innovative solutions to address these challenges. With advanced steam management systems, automation packages, and efficient boiler blowdown and condensate recovery solutions, Forbes Marshall helps textile plants optimise steam usage, reduce fuel consumption, and recover lost energy.