Steel

Optimising Efficiency. Driving Sustainable Growth

Whether it’s an existing plant, an expansion, or a greenfield project, our engineered solutions and services optimise energy consumption, improve operational performance, reduce water usage, and minimise environmental impact for efficient and sustainable steel production.

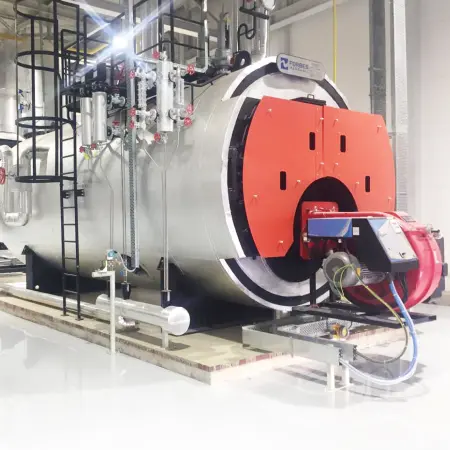

The steel industry is experiencing significant growth globally, driven by demand from infrastructure, manufacturing, and automotive sectors. However, steel manufacturing remains highly energy and water-intensive, with high production costs and sustainability challenges. Forbes Marshall, with over 75 years of experience, provides innovative solutions to help steel manufacturers improve energy efficiency, optimise water usage, and reduce their environmental impact. From small metal producers to large integrated steel plants, our fully engineered solutions for the steel plant, covering the boiler and turbine house, all processes from the raw material to the finished product, as well as water and effluent treatment help address bottlenecks and conserve energy, offering a typical return of investment of less than a year.

Our process and energy efficiency solutions are designed to improve system performance and product quality while minimising resource consumption. Our advanced monitoring and control systems for key parameters such as pressure, temperature, and flow, enable steel plants to operate at benchmark efficiency levels. Additionally, our solutions for condensate and steam recovery, oxygen enrichment, and air efficiency optimisation help reduce utility consumption. We also offer a comprehensive range of environmental monitoring tools to ensure compliance with emissions regulations and reduce water footprints, while our predictive maintenance solutions increase plant uptime and enhance safety.

Let us help you

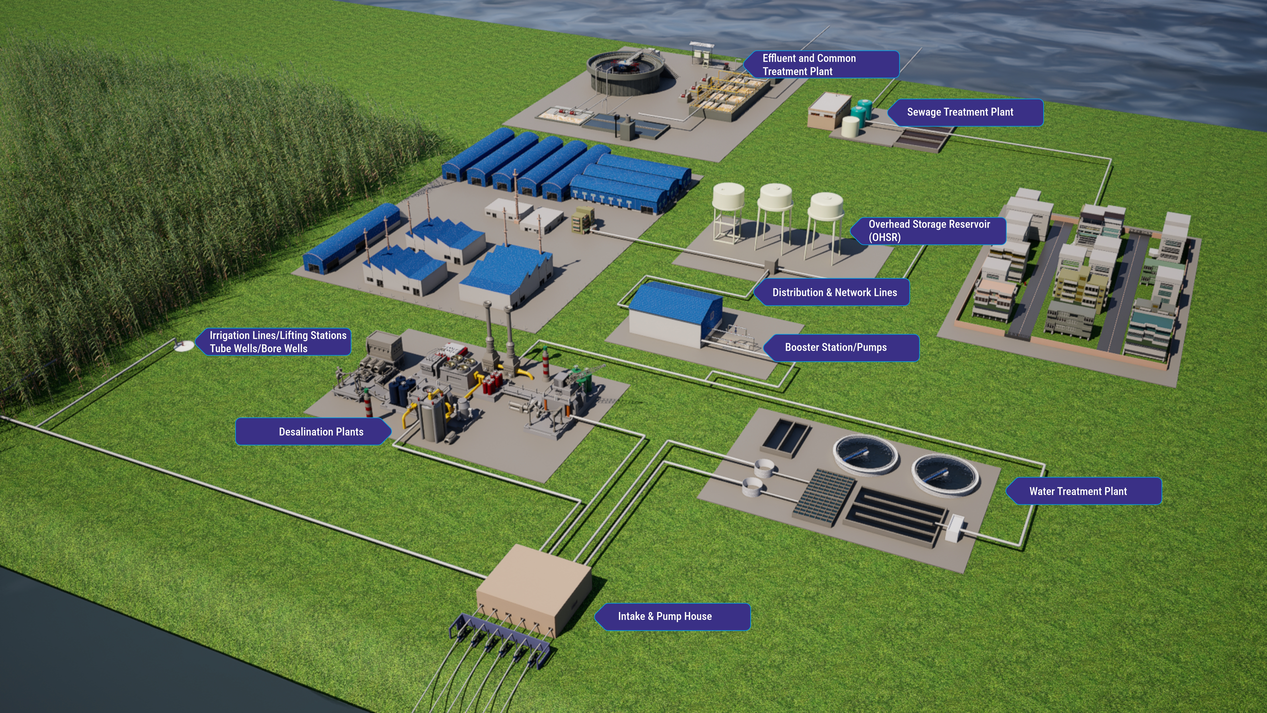

Water and Wastewater

Explore our solutions for the chemical and API industry.

Effluent and Common Treatment Plant

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Sewage Treatment Plant

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Overhead Storage Reservoir (OHSR)

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Distribution & Network Lines

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Booster Station/Pumps

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Water Treatment Plant

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Intake & Pump House

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Desalination Plants

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,

Irrigation Lines / Lifting Stations Tube Wells / Bore Wells

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s,