Clean-in-place (CIP)

Hygiene is of utmost importance in the brewing process. The most common method used to achieve this is the Clean in Place (CIP) process, with the help of a CIP system. The CIP system enables the cleaning of the interior surfaces of process pipes, tanks, vessels after each batch / at specified intervals to maintain food safety and hygienic production. The steps in the cleaning sequence, right from pre-rinse to sanitising and drying, can be automated.

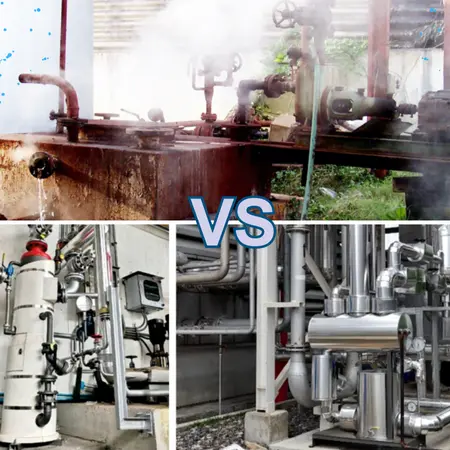

We find that the actual CIP time is often high due to the time taken to achieve the desired temperature during heating. This deviation impacts the production cycle. Temperature overshoots in the tanks are also observed, which contribute to a higher MJ/HL.

Our Solution:

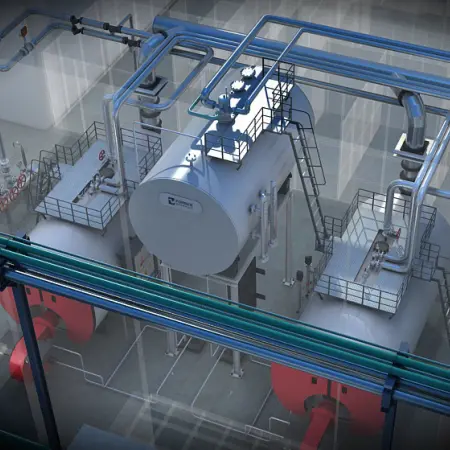

Forbes Marshall addresses the gaps in the steam system design by