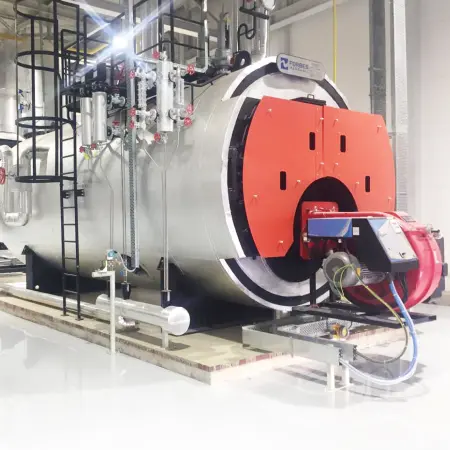

Steam is a critical resource for the food industry. Whether producing snacks, ready-to-eat (RTE) meals, noodles, confectionery, coffee, tea, or canned foods, steam ensures efficient, safe, and high quality processing, right from cooking and sterilisation to drying and pasteurisation. Accurate control of steam temperature, pressure, and distribution helps maintain product integrity, minimise contamination risks, and comply with food safety standards.

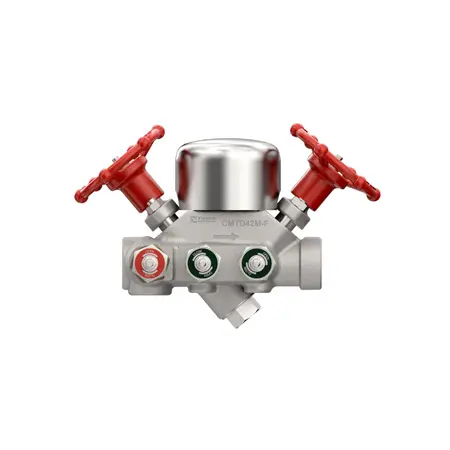

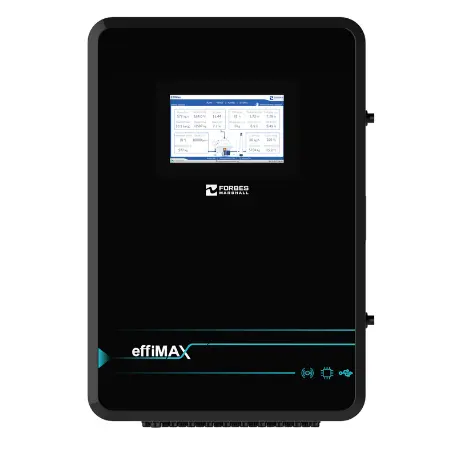

Forbes Marshall offers a complete range of steam and instrumentation solutions tailored specifically for the food industry. Our offerings include advanced boiler controls, steam accessories, flow and level metres, control valves, water quality analysers, condensate recovery systems with an emphasis on energy conservation, process efficiency, and sustainability. Through these custom solutions we help food manufacturers maintain product consistency while achieving substantial savings.