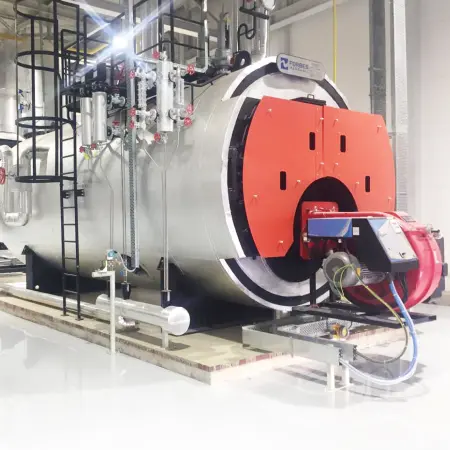

Wort Kettle

Wort boiling is the most thermal energy intensive process in brewing, and consumes about 30% of total plant steam. Proper wort boiling is essential for achieving the desired beer quality and optimising productivity and energy consumption.

Plants often face challenges in maintaining key parameters like evaporation ratio and outlet degree plato, which vary across batches because of the common practice of setting a fixed boiling time.

Variation in inlet degree plato and wort inlet (preheating) temperatures impacts both, evaporation rate and batch time. Temperature overshoots due to manual operations, higher than required steam pressure, and bypassing steam traps to evacuate condensate impacts energy consumption, which often exceeds the theoretical requirement by 25-30%

Conventionally designed wort vapor heat recovery systems are unable to effectively utilise the full amount of waste heat resulting in additional steam and time for wort boiling.

Our Solution:

The holistic solution from Forbes

Marshall encompasses