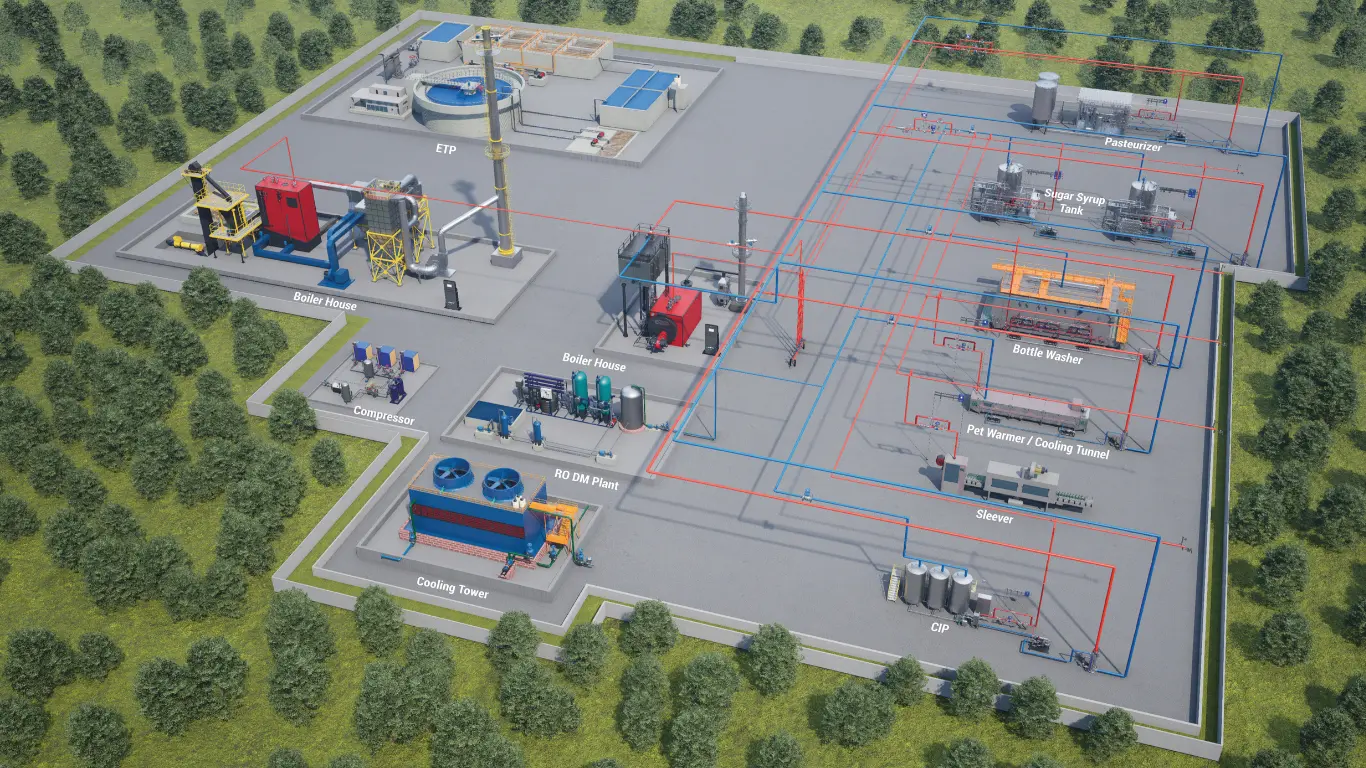

Beverage manufacturing is complex, requiring both significant water and energy use. Plants must ensure consistent product quality, uphold food safety standards, reduce the beverage-to-fuel ratio, and aim for sustainable operations.

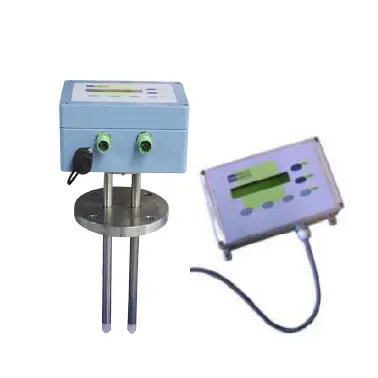

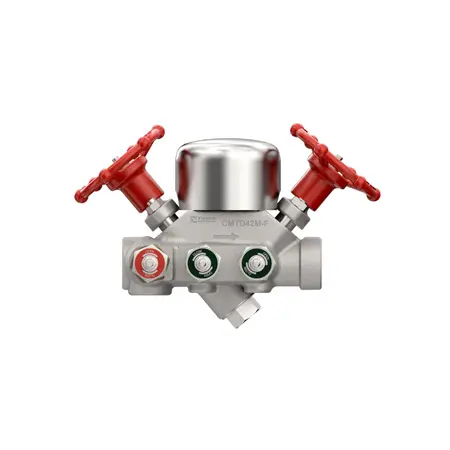

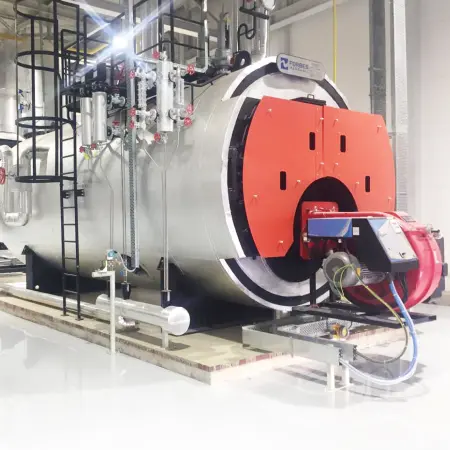

Water quality directly affects both product quality and consumption safety. Meanwhile, a well-optimised steam system not only ensures consistent quality, but also boosts productivity and reduces energy consumption.

Forbes Marshall collaborates with beverage manufacturing plants to fine-tune steam and water systems, driving efficiency, lowering costs, and promoting sustainable operations.

Let us help you