Energy Conservation Tips

Welcome to Forbes Marshall’s repository of energy conservation tips for steam systems. If you want to reduce fuel consumption, improve productivity, sustain performance, and lower your plant’s carbon footprint, you’re in the right place. These simple and effective tips will help you make your steam processes more efficient and sustainable across steam distribution piping, steam process utilisation, steam generation, and condensate recovery.

These tips are designed to help plant operation and maintenance managers, energy managers, and utility heads optimise steam systems.

Condensate is almost 20% of the fuel energy

Flash Steam Holds 50% of the Energy Content of the Condensate

Open vessels containing heated fluids should be covered

Advantages of Returning Condensate to Feedwater Tank

Return condensate as soon as it is formed.

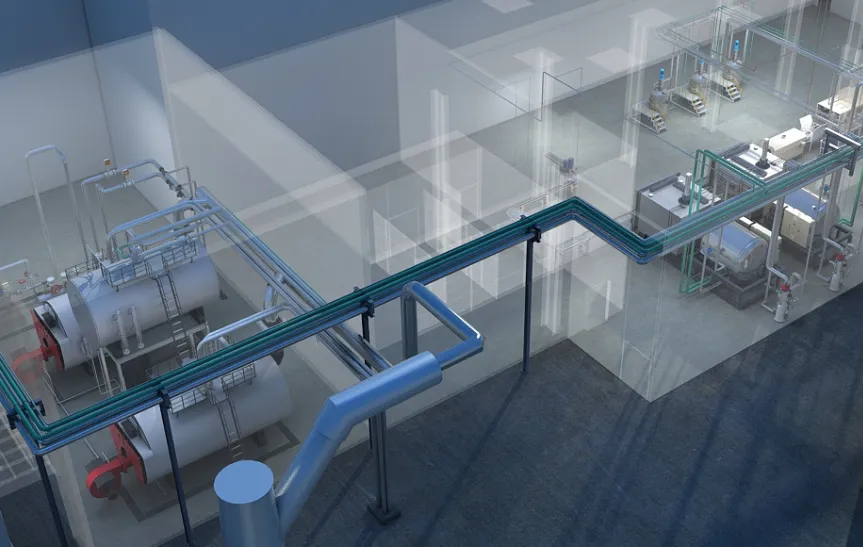

Ensure Maximum condensate is returned to the feedwater system.

Condensate should be recovered.

Mixing high pressure and low pressure condensate increases the back pressure.

Returning condensate by trap pressure often results in reduced condensate evacuation

Flash steam should be separated from condensate while returning the condensate to feedwater tank.

Recover Flash Steam From Contaminated Condensate

Use Steam at the Lowest Possible Pressure for Indirect Heating

Use Steam Traps to Drain Condensate

Steam line tappings for equipment must always be taken from the top of steam pipes

Eliminate air steam system to ensure effective heating and thus fuel savings.

Advantages of Steam Operated Pumps

Tappings for steam traps should be taken through correctly sized drain pockets.

Keeping the insulation dry reduces radiation loss and thus saves fuel

Small leaks cost big money

Wet steam reduces the process efficiency

Avoid group steam trapping at the process equipment level

Individual trapping lowers process time and reduces steam consumption.

Identify stall condition and take corrective actions.

How Condensate Return Reduces Boiler Blowdown

Finned Tubes vs. Bare Tubes in Air Heat Exchangers

Stall increases steam consumption and process time

Use saturated steam for indirect heat transfer applications

Circulation pumps are not needed for hot water and thermic fluids

Stall increases steam consumption and process time of the heat exchanger

Using multi effect evaporators in place of single effect evaporators reduces the steam consumption by about 1/3rd.

Utility flows should be measured accurately.

During product drying, lumps should be broken into smaller pieces

Strainers should be installed correctly so that they do not become a source of wetness

To reduce steam consumption, a pressure reducing station should be opted for

On Steam heating applications controlling the temperatures to set point avoids excess steam consumption

For hot water systems, use indirect heat exchangers in place of direct injection based systems

Insulate oil tank in the tank farm

Use Indirect Heating for Hot Water Generation

Use Saturated Heat for Utilization in the Process

Use Diffusers at the Point of DIscharge for Steam Traps DIscharging to Atmosphere

Installation of a Vacuum breaker protects the process equipment

Use Vacuum Breakers on Small Heat Exchangers to Avoid Stalling

Moisture Separators Should be Insulated

Installing View Glass After a Steam Trap Eases the Maintenance

Installation of a Vacuum breaker protects the process equipment

The Temperature of Furnace Oil Day Tank Should be Regulated.

Balanced Pressure Thermostatic Steam Traps Should be Used for Tracing Applications

The Temperature of Furnace Oil Day Tank Should be Regulated.

Correct Installation of Air Vents

Correct Installation of Steam Traps

Install moisture separators to maintain dryness of steam.

Correctly sized steam mains are critical.

Importance of correct application based steam trap selection

Why Redundant Steam Lines Must Be Removed or Properly Blinded

Effective control while de superheating steam is critical to avoid steam losses.

Accumulated condensate in steam lines can lead to noisy and damaging water hammer

Steam Mains should be engineered to facilitate flow of condensate by gravity to the steam trap

Long saturated steam distribution lines should be sized on pressure drop method.

Use Steam Flow Meters With Ability to Compensate for Change in the Density

Pipe sizing should be done correctly to avoid losses during steam distribution

Increase in TDS levels in the feedwater tank leads to water carry over thereby increasing fuel consumption.

Monitor flue gas temperatures to control stack loss.

Co-generation plant operations should be decided only after comparing the running cost to cost of electricity.

Using steam instead of thermic fluids for indirect heating is more efficient.

Monitoring flue gas temperature gives a good indication of the boiler operating conditions

Boilers efficiency should be monitored.

At part loads the most efficient boiler should be used.

Poor quality of fuel leads to poor boiler efficiency.

Operating boiler closer to full load improves efficiency

The configuration of the co-generation system is important to ensure high efficiency

Chemical treatment of make up water increases the TDS levels in the boiler

Avoid Frequent Changes to the Boiler Fuel Firing System

Increase the inlet air temperature to increase boiler efficiency

Higher feedwater temperature increases the boiler output

Avoid High Negative Draft in Solid Fuel Fired Boilers

Why Saturated Steam Is Better for Heat Transfer Than Superheated Steam

Generate Steam at Higher Pressure

Why Steam Is a Better Heating Medium Than Thermic Fluid

The TDS inside a boiler should be maintained at recommended levels

Maintaining high TDS levels in the boiler drum results in water carryover

Dissolved oxygen should be removed from the feedwater tank

Avoid over sizing the boiler

Shell type steam boilers offer better fuel efficiencies as compared to coil type boilers.

Understanding and Improving Your Steam-to-Fuel (S:F) Ratio

Co-generation plant operations should be decided only after comparing the running cost to cost of electricity

Feedwater tank should be sized to be 1.5 times the peak steam demand.

Injection of flash steam and condensate into the feedwater tank should be via a deaerator head

Minimize Boiler Scaling

High feedwater temperature drives out dissolved oxygen

Opting for shell type boilers over coil type boilers leads to availability of good quality steam

Measuring specific fuel consumption gives a true reflection of your plant efficiencies

Air to fuel ratio should be monitored and controlled to minimize unburnts

Flue gas temperatures are a good indicator of excess air

Safeguarding Boilers against Fuel Explosion

Importance of Steam Trap Selection and Sizing

Use shell type boiler to recover condensate.

Every 6°C rise in feedwater temperature reduces the fuel bill by 1%.

Referencing the boiler efficiency to the GCV of the fuel rather than the NCV gives a more accurate picture

Black or White Smoke is an Indicator of Improper Combustion

Efforts should be made to minimize addition of surface moisture content in fuel.

Maintaining the right level of water in the feedwater tank reduces the overall boiler feedwater TD

The Temperature of Furnace Oil Day Tank Should be Regulated

To deliver the same amount of energy, the flowrate of hot water will have to be 45 times than that of steam