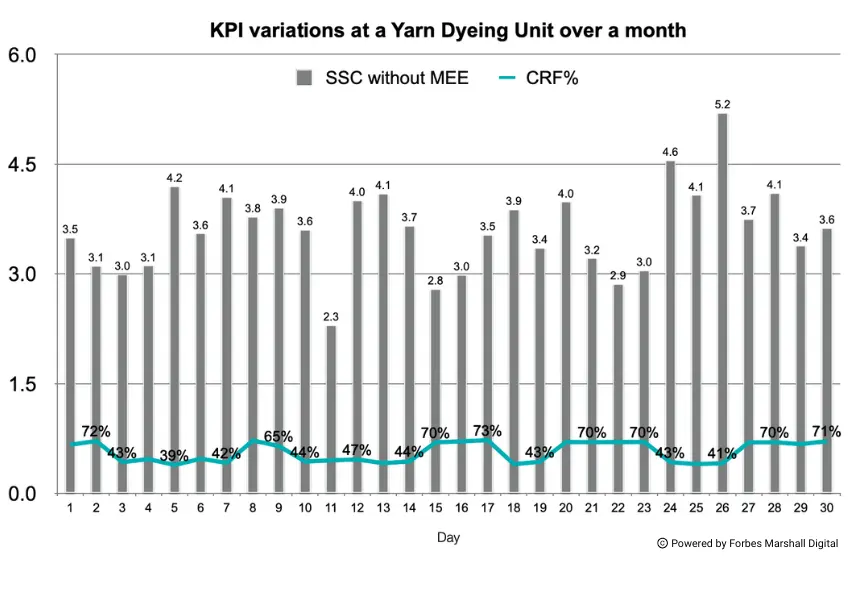

On average, plant level KPIs vary between 25-40%. This can be improved and sustained to a variation band within 10% through our knowledge based services.

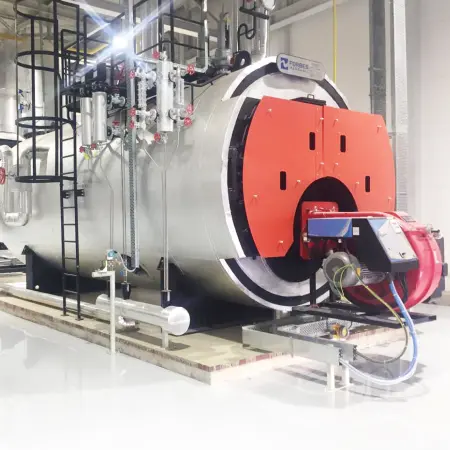

Numerous variables, such as production loads, seasonal requirements, operating practices, operator competencies, inadequacy of monitoring systems, lack of real-time data, and product mix, impact a plant’s performance. This results in increased production costs and can also impact the quality of production. A holistic view of a plant’s operation ensures each utility is considered when optimising overall consumption, leading to a sustainable, efficient plant. From your boiler house, to your entire steam, water and air systems, Forbes Marshall provides continuous, accurate, real-time data monitoring and regular diagnostic reports of your plant including actionable insights to sustain KPIs. This ensures that uptime increases, maximising production capability and ensuring production quality is maintained.

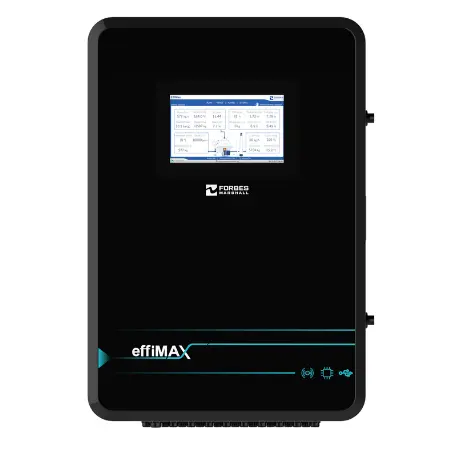

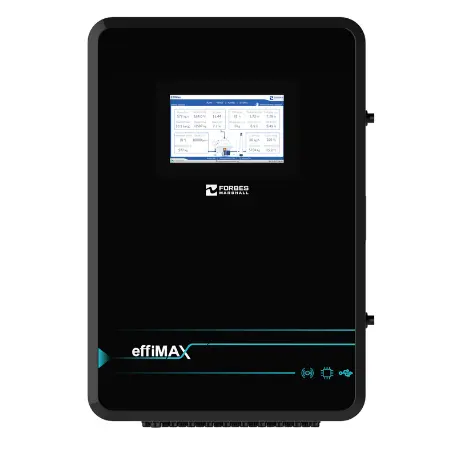

Key parameters we monitor

Condensate recovery

Specific Steam Consumption

Specific Water Consumption

Steam: Fuel Ratio

Steam System Score

Uptime of Utility System

And other utilities like air and power

We provide actionable insights

Delivering Benefits

Our

footprint

Our footprint across services

Our

footprint

across services

footprint

across services

500

Plants

1200

Assets

7500

Parameters