Improving Uptime and Productivity of the Pasteurisation Process

Customer: A leading beverage manufacturer in Thailand

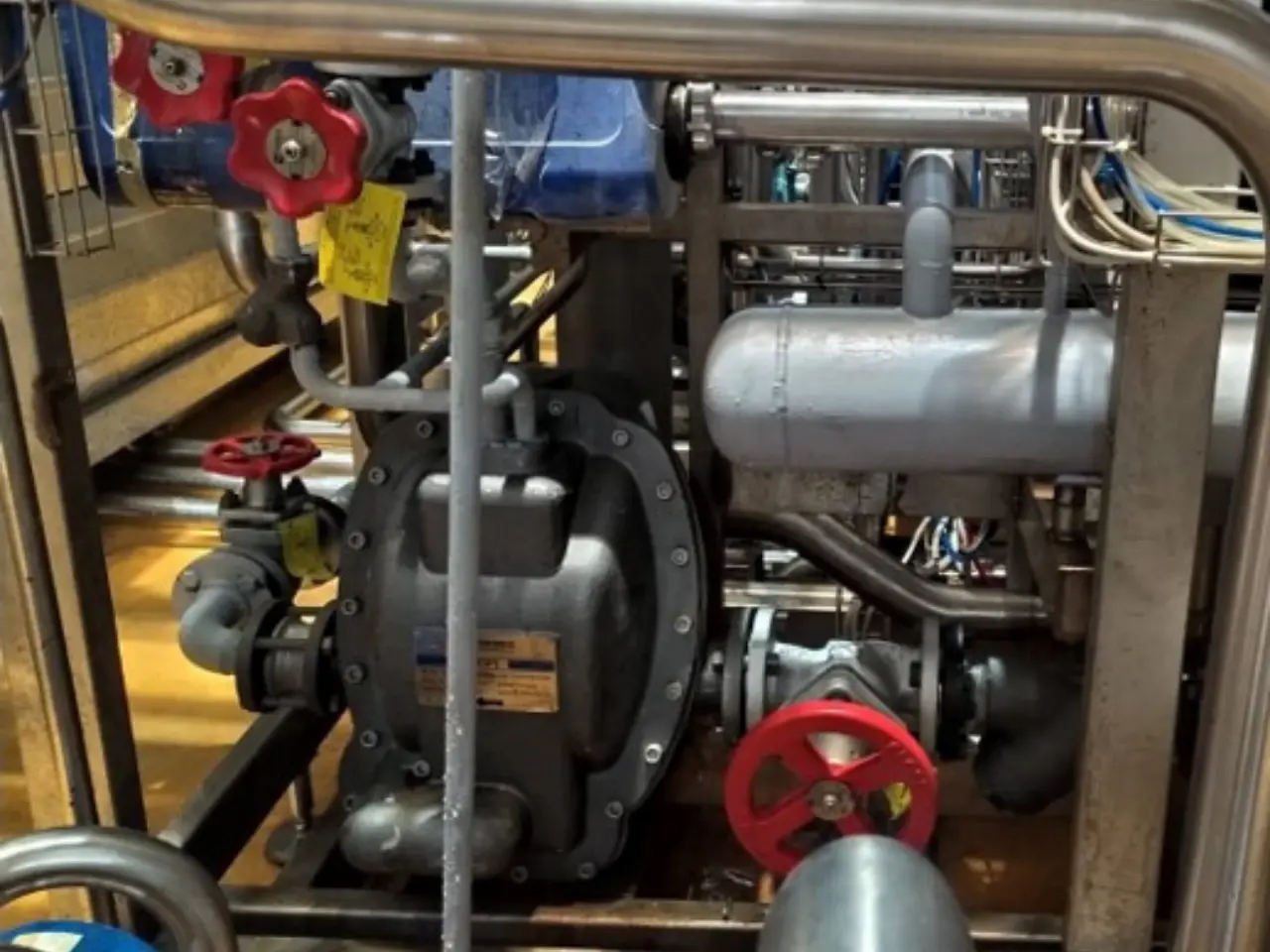

The plant was experiencing difficulties in attaining the desired pasteurisation temperatures. This was significantly impacting plant productivity. The issue was linked to a conventional float trap which was unable to evacuate condensate from the heat exchanger during stall.

Forbes Marshall engineers conducted a thorough analysis and developed a holistic solution. Following implementation, the process operated without stalling and eliminated the need to bypass the steam trap. The plant was able to achieve uniform pasteurisation temperatures, reduce Plate Heat Exchanger (PHE) downtime and associated maintenance costs, and enhance system safety.

What to read next

Products

Associated Services

Process Optimization

Improving Uptime