Eliminating Steam Pressure Fluctuations and Enhancing Condensate Recovery for Optimal Plant Efficiency

The plant was experiencing persistent steam pressure fluctuations between 4-6 barg along the mainline, primarily due to frequent bypass openings caused by a malfunctioning control valve. Additionally, the plant was facing issues of delayed start-ups at the bottlewasher and difficulty in reaching the required process temperatures in the warmer.

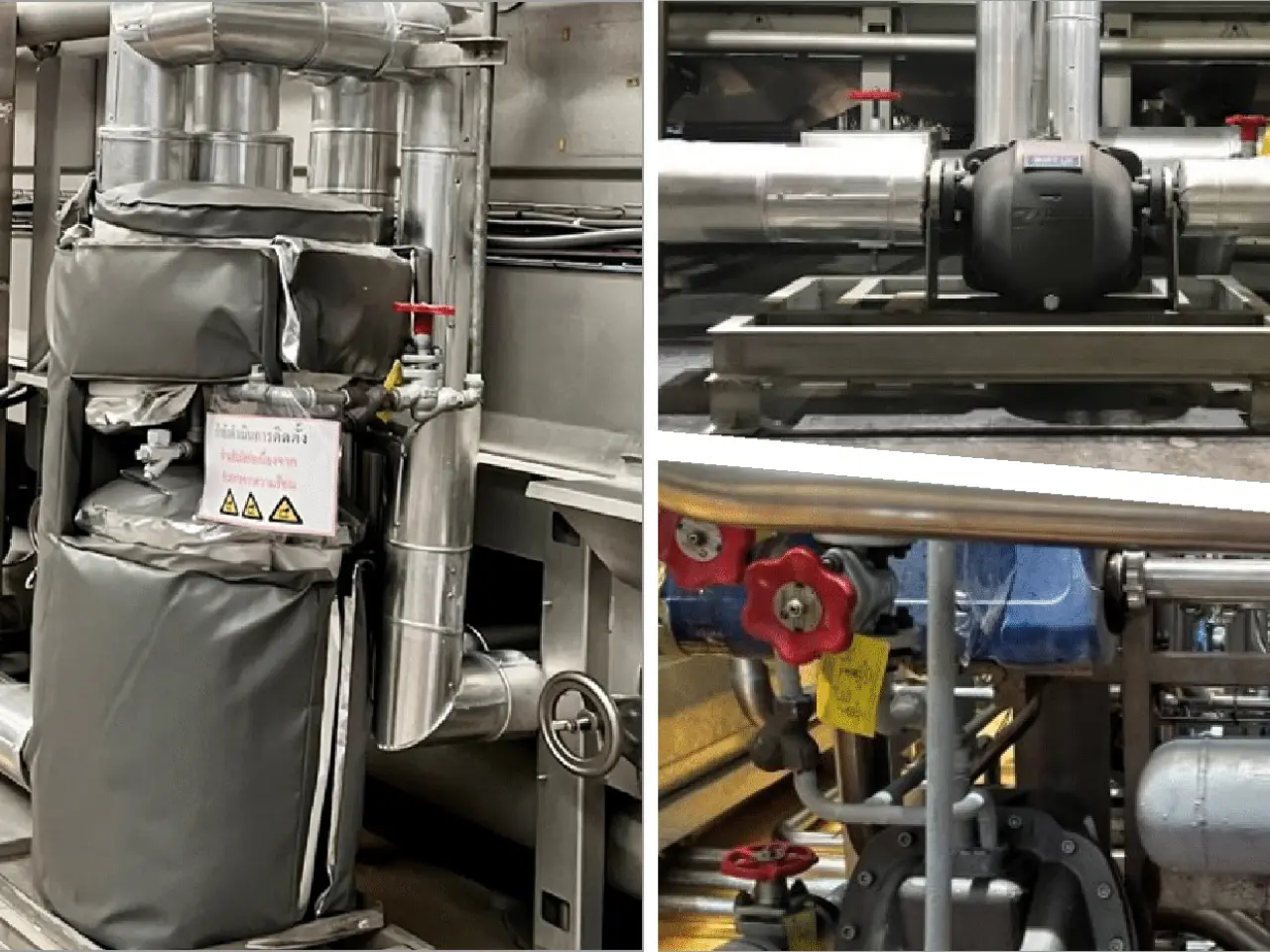

Forbes Marshall engineers conducted a detailed plant audit. We identified that steam pressure fluctuations were due to a malfunctioning control valve, while in the warmer, condensate recovery by trap pressure was causing excessive back pressure on the steam trap, leading to frequent bypass openings and failure to achieve the desired temperature set point. The float-type steam trap on the bottlewasher could not fully evacuate condensate during stall, delaying startups and requiring the trap to be bypassed to attain process temperatures. These issues were also leading to localised condensate drainage.

What to read next

Products

Associated Services

Process Optimization

Improving Uptime