CASE STUDY

Ensuring borewell availability and water accountability at a power plant using EverSense for Groundwater Extraction Management

Ensuring borewell availability and water accountability at a power plant using EverSense for Groundwater Extraction Management Improving CRF by 25% at a pharmaceutical plant, using EverSense for Condensate Recovery Factor

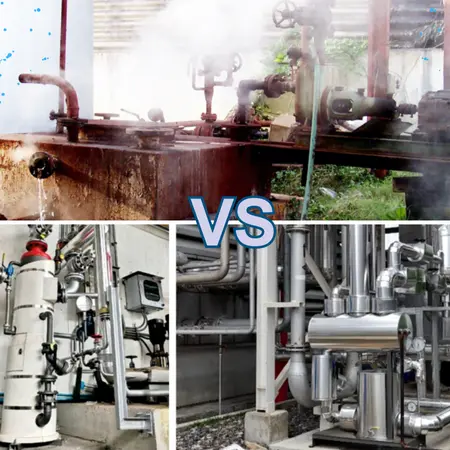

Improving CRF by 25% at a pharmaceutical plant, using EverSense for Condensate Recovery Factor Reducing steam consumption and OPEX at a leading fragrance specialty chemicals manufacturer in South Asia

Reducing steam consumption and OPEX at a leading fragrance specialty chemicals manufacturer in South Asia Reducing energy consumption at a leading manufacturer of organic and inorganic and effect pigments in South Asia

Reducing energy consumption at a leading manufacturer of organic and inorganic and effect pigments in South Asia