Online Steam Wetness Measurement

With increasing populations and growth in industrialization demand for power across the world is steadily on the rise.

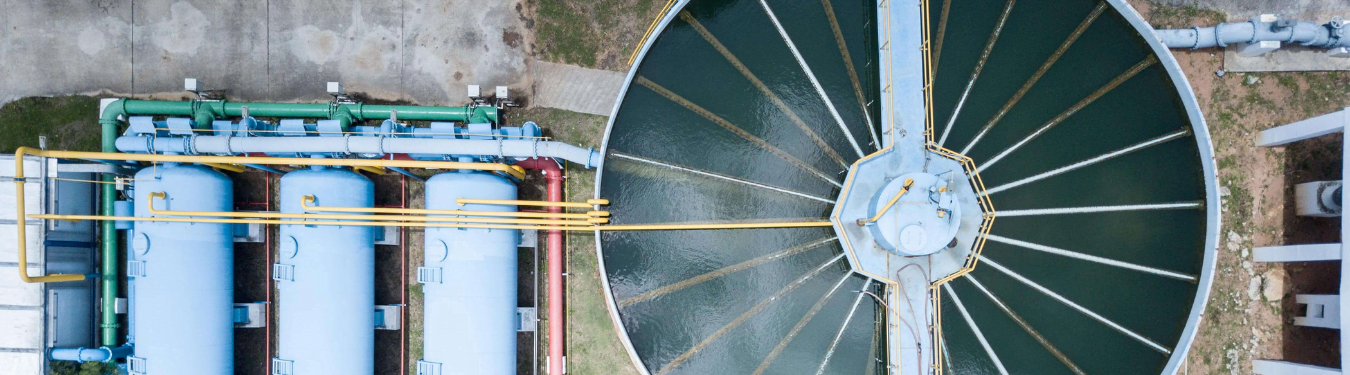

Power plants are broadly classified into hydroelectric, thermal, solar and wind. Thermal power stations convert heat energy to electric power through a steam turbine. In order to ensure that power plants run efficiently, it is necessary to maintain the quality of steam.

Nuclear Power Plants

In a typical nuclear power cycle, steam generated from the reactor is used in the HP steam turbine.

It is also used IP and LP steam turbines after passing through the moisture separator re-heater (MSR).

The smallest increase in steam moisture can result in a substantial drop in steam turbine efficiency.

It also adversely impacts steam turbine life due to mechanical carryover.

Both steam quality and purity play an important role in ensuring safe and efficient operation of steam turbines.

Geothermal Steam Cycle

Geothermal power plants utilize heat energy from the earth. Geothermal power plants can either be dry steam power stations, flash steam power stations or binary cycle power stations. In dry steam power stations, hot steam from below ground level is fed directly to the turbines. Generator turbines of flash steam power stations are driven by steam generated from high pressure hot water from geothermal wells. In case of binary cycles, thermic fluids at higher pressures carry the heat from geothermal wells, which is then converted to steam for power generation.

Dry Steam Cycle Flash Steam Cycle

However, steam generated in geothermal power plants is wet steam. Steam generated in these plants also carry highly corrosive gases like H2S. Separators are therefore necessary to remove moisture from steam.

Online Steam Wetness Measurement

For any steam turbine supplier, carryover of impurities from steam is a big concern since it directly affects performance and operation of the turbine.

Steam drums are equipped with steam separation devices capable of mechanically reducing the moisture content of steam.

Dissolved and suspended solids are introduced into steam through boiler water carry over. The total carryover into steam can be categorized as

– Mechanical, that is carryover of boiler water droplets.

– Vaporous, which involves the partitioning of dissolved solids (salts, oxides, impurities and other chemicals) between water and steam and represents the physical volatility.

Mechanical carryover is a major concern for nuclear and geothermal power plants.

In most conventional (fossil fuel based) thermal power plants steam turbines are operated on superheated steam. Mechanical carryover in saturated steam can cause serious corrosion and erosion problems for the super- heater as well as the steam turbine.

In case of nuclear, geothermal and solar thermal power plants, steam at the outlet of the steam generator is very similar to saturated steam. Mechanical carryover (steam quality) is a critical concern in such power plants.

Hence, these plants are equipped with moisture separators and dryers which ensure final moisture content of less than 0.26% in the steam at the inlet of the high pressure turbine.

As established, increase in steam wetness directly contributes to the loss of output from the steam turbine and hence steam wetness measurement is very important for nuclear and geothermal power plants. Throttling calorimeter based wetness measurement is the most widely used thermodynamic method for detection of steam wetness.

Typical layout of a steam wetness measurement system that helps to detect steam wetness from 0% to 5%.

Categories

Tags