How does Forbes Marshall Digital go #BeyondConnectivity, and why is it important for industry?

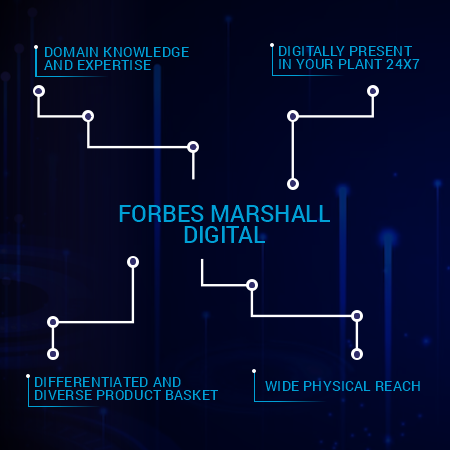

#BeyondConnectivity at Forbes Marshall is a combination of 4 key aspects of our business approach which is designed for a holistic digital solution experience. Our journey began in 2019, when we started considering the future of Industry. As with all of our R&D, we look to solve real issues faced by plants globally – across industries, varied plant sizes, etc. These inputs come from our customers and our sales and service specialists in the field. Through this, we realised that there would be numerous benefits of having a plant, or specific areas of a plant digitally connected. But we did not want to just provide connectivity. Which brings us back to our 4 key aspects of #BeyondConnectivity:

Domain knowledge and expertise

Based on our decades of experience across 100s of plants catering to over 30 industries – ranging from sugar to steel and pharmaceuticals to power. By dealing with various challenges across industry segments, our teams are equipped to address these challenges hands-on, ensuring your plant can increase production, improve product quality, lower the cost of production while reducing the impact your plant has on the environment.

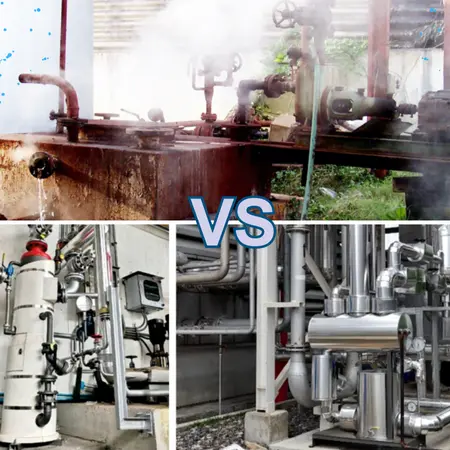

Differentiated and diverse product basket

Our extensive, robust product offerings provide numerous solutions addressing process and energy efficiency through steam engineering and control instrumentation. Over 70% of our product range is digitally enabled – ensuring we are best placed to provide quick, efficient support both remotely and on-site. Additionally, Forbes Marshall’s focus on R&D is amongst the highest in the Indian engineering sector and matches world class benchmarks. Our R&D facilities in India and the UK focus on addressing the future needs of industry, while maintaining a strong design philosophy as it is key for environmental sustainability, looks, functionality and life cycle.

Fun fact: Our Co-Chairman, Naushad Forbes, has always believed that great products are ‘and’ products – products that are beautiful and functional, elegant and simple, high quality and accessible to a wide strata of the population. It is the task of great design to deliver on that ‘and’. This has been a key element of Forbes Marshall’s strategy for over three decades.¹

In your plant 24×7 – digitally!

Our engineers are always with you, even when we are not physically present. We securely digitally enable only relevant areas of your plant, analysing real-time data and providing actionable insights to keep your operations running smoothly. We also empower your plant personnel through knowledge sharing and training sessions, ensuring that they are able to take immediate corrective actions based on our suggestions. All of which is aimed at increased uptime, reliability, safety, and process and energy efficiency.

Wide physical reach

Since Forbes Marshall’s inception in 1946, we have grown to

>500 sales and service specialists based across 37 offices globally, who collectively on average visit 1250 customers daily;

6 integrated manufacturing facilities across India, Singapore and the United Kingdom;

and 18 distribution centres.

We take great pride in our long-term relationships with our customers. This relationship has been built on trust and care. Even in countries or regions where we may not have an office yet, our sales and service specialists are fully equipped to travel at the earliest and provide complete support. Hence, along with being digitally enabled, if the data brings to light a more critical issue which cannot be handled by plant personnel, we will be at site – ensuring safety and reducing impact on your production.

How can Forbes Marshall Digital improve your process?

To know more about our digital solutions explore https://www.forbesmarshall.com//digital

Citation: ¹Forbes, N. (2022). Design: The Scale India Needs. The Struggle And The Promise. (pp 141-143) Harper Collins