Thermocompressor Systems

Forbes Marshall Thermocompressors are ideal for recovering flash steam from high pressure applications and using it for low-medium pressure applications. Thermocompressor systems directly bring down the fuel consumption of the steam plant.

The Thermocomporssor efficiently mixes the low pressure flash steam with the high pressure motive to generate dry, saturated steam at low-medium pressure. Thermocompressors have demonstrated maximisation of flash steam recovery and condensate removal from applications like drying drying cylinders by providing effective ‘blow off’.

They have a reliable and robust design and are validated on a comprehensive, well instrumented test rig. every compressor is custom built to suit specific industry needs and can be seamlessly integrated into the existing control system.

- A monolithic system without any moving parts. Truly fit and forget technology.

- Custom approach ensures that every thermocompressor works at optimum level over its entire lifecycle.

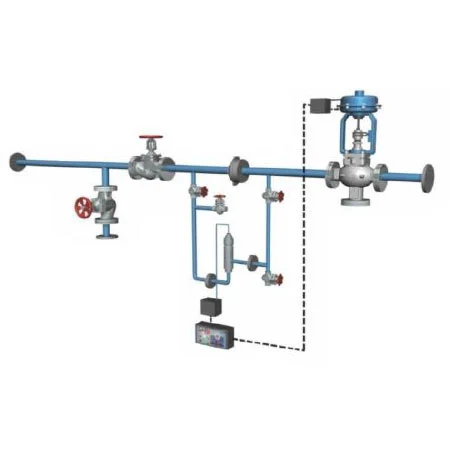

- Comes as a full package with safety valves, check valves, strainers and other components for hassle-free installation.

- Brings down the fuel, water and water treatment costs.

- Can bring down steam consumption by as much as 20%.

Maintenance Schedule

Brochure

Have a project in mind that you think we’d be a great fit for it? We’d love to know what you’re thinking

Get in Touch

Frequently Asked Questions

No accordion items found.