Insulation

Heat naturally flows from a warmer to a cooler area. Heat present in condensate is dissipated to the surrounding environment due to radiation and convection, causing the condensate temperature to decrease.

The impact of a drop in condensate return temperature on the feed water tank temperature and boiler fuel consumption is illustrated below.

The illustration is worked out for every 5 Degree C gain/drop in condensate return temperature for different CRF% scenarios.

| Condensate Recovery Factor (CRF) % | |||||

|---|---|---|---|---|---|

| Every 5°C gain/drop in condensate return temperature | 50% | 60% | 70% | 80% | 90% |

| Results in a gain/drop in feed water temperature by | 2.5°C | 3°C | 3.5°C | 4°C | 4.5°C |

| Results in a gain/drop in boiler fuel consumption by | 0.4% | 0.5% | 0.6% | 0.7% | 0.8% |

Insulation, made up of materials which are poor conductors of heat, acts as a barrier and restricts the flow of heat from the condensate to the surrounding environment.

Insulation also prevents safety hazards of scalding by lowering the exposed surface temperatures of condensate pumps, pipelines and tanks and additionally reduces the overall ambient working temperature.

Care should be taken to insulate condensate pipelines, condensate pumps, flash separation vessels and the feed water tank. Ideally, the surface temperature of the insulation cladding should not exceed the ambient temperature by more than 10oC. The health of insulation should be checked periodically by thermography.

Guide to selecting insulation material

While different options for insulation are available, the table below provides details of commonly used insulation materials.

| Insulation material | Application temperature (°C) | Standard densities (kg/m³) | Notes |

|---|---|---|---|

| Rock wool | -200 to 900 | 60 to 160 | Chemically inert, non-corrosive, non-combustible |

| Glass wool | -200 to 450 | 10 to 80 | Abrasive and should not be used in the food industry |

| Perlite (expanded) | -250 to 1,000 | 50 to 150 | Chemically inert, non-combustible |

| Ceramic fibre | Up to 1,250 | 64 to 192 | High temperature stability, non-combustible |

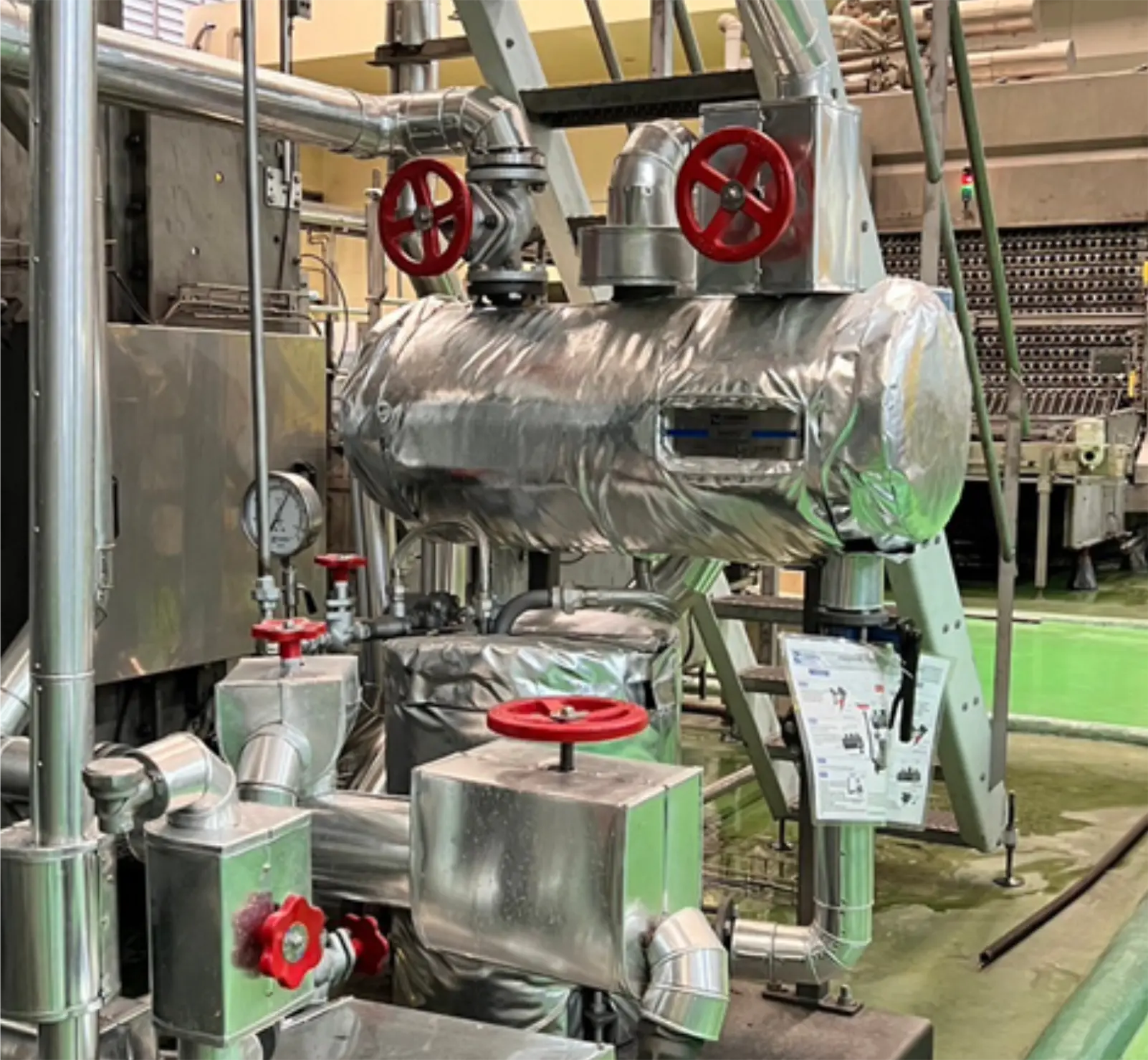

Removable insulation for condensate pumps and flash separation vessels

Removable insulation jacket

Accessories are often left uninsulated due to the need to carry out periodic maintenance on them. Removing and re-fixing conventional insulation is both time consuming and cumbersome.

Removable insulation jackets address this issue. They are available for a wide range of accessories including valves, flash separation vessels and condensate recovery pumps.