Recover flash steam to the boiler feed water tank

Flash steam can also be reclaimed back to the boiler feed water tank. However, when recovering flash steam to the boiler feed water tank, two considerations should be taken into account. Firstly, if the boiler feed water tank operates at atmospheric pressure, the addition of flash steam should not raise its temperature beyond 90°C as this will result in boiling in the feed tank leading to significant vibrations and

possible damage to the tank as well as heat loss from the tank. Second, it is important to ensure that the distance between the flash steam generation source and the boiler feed water tank is not excessive, as this could cause the flash steam to condense before reaching the feed water tank. Flash steam to the feed water tank should always be routed through a deaerator head to enable proper mixing of flash,

condensate and make up water. In the absence of a deaerator, flash steam will not completely quench and will partially vent out of the tank as seen in the illustration below.

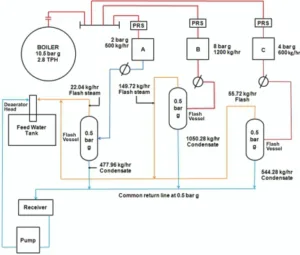

A typical schematic for recovery of flash steam to the boiler feed water tank is illustrated below.

Figure 24: Flash steam and condensate recovery to the boiler feed water tank (Actual plant images)