Paper Machine Paper Drying Systems

Paper, as is commonly known, is made from the fibre of trees. Paper production can be

broken up into two main processes :

- converting the fibre to pulp and then the pulp to paper

The entire process of conversion from fibre to the finished product is complex and integrates many different sections in a paper mill.

Process Flow in an Integrated Paper Mill

Steps in the paper making process :

- Pulping – to separate and clean the fibers

- Refining of pulp

- Dilution – for a thin fibre mixture

- Screening – for formation of fibres

- Pressurization – to enhance density

- Drying – to eliminate the density of materials

- Finishing – to provide a suitable surface for use

Excess moisture content in paper can lead to breakage and rejection. Proper selection of the drying system is therefore crucial to the quality of the final finished product.

Factors to be considered while selecting a paper drying system

The main objective of a paper drying system is to evacuate condensate from inside the drying cylinders properly and utilise steam efficiently. The appropriate paper drying system needs to be decided based on the condensate behavior inside the drying cylinders. Condensate behavior inside the drying cylinder depends upon the operating speed. Higher the speed, higher the centrifugal force on condensate in the opposite direction, making condensate evacuation from inside the drying cylinders difficult.

Behaviour of condensate inside drying cylinders at various operating speed ranges

| Machine | Condensate Behavior |

| 0-200 MPM / 0-660 FPM | – Condensate puddles at the bottom of the cylinder – Does not move in the direction of dryer rotation

– The syphon tip always remains dipped inside the puddle, and only condensate moves through the syphon |

– Condensate puddles at the bottom of the cylinder

– Rotation of the cylinder causes the puddle to move, but shell gravity overcomes centrifugal forces and the condensate is pushed back towards the puddle at the bottom

– The syphon tip always remains dipped inside the puddle, and only condensate moves through the syphon.

– Condensate moves in the direction of dryer rotation

– With increase in speed of dryer rotation, centrifugal forces overcome gravity forces so that condensate film formed around the dryer is of uniform thicknesses

– The syphon tip gets exposed to live steam – The condensate and blowthrough steam move through the syphon

As can be seen from the table above, the scenario inside the drying cylinders greatly differs according to the speed of the paper machine. It is not possible for a single solution to handle these varying conditions. The two types of systems available are steam trap based and blow through based drying systems. Blow through based drying systems are further classified as thermo-compressor based or cascade based.

Steam trap based paper drying systems

A steam trap based paper drying system is suitable for lower paper machine speeds. At lower speeds, the syphon tip inside every dryer remains dipped inside the puddle of condensate, and only the condensate moves through the syphon.

Steam traps can efficiently remove condensate from all drying cylinders at lower speeds. After the condensate is removed, flash steam gets generated from the condensate. This flash steam should be recovered back in paper machine dryers to ensure optimum steam consumption in paper drying process.

Blow through type paper drying systems

Blow through based paper drying systems are ideal for handling conditions arising in the drying cylinders of high speed machines.

Thermocompressor based blow through systems

At higher speeds, a mixture of condensate and blow-through steam moves through the syphon. Evacuating the condensate through a steam trap may be difficult as blow-through steam locks the steam trap. The locked steam needs to condense before the condensate can exit and, till then, gets accumulated inside dryers. Repeated steam locking necessitates opening of the bypass valve to manually allow condensate out. Due to opening of bypasses, paper drying efficiency reduces and steam consumption increases.

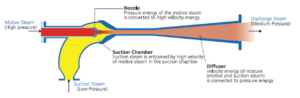

In a thermocompressor based system, the complete condensate and blow through steam mixture exits from the dryer. This mixture, from a set of cylinders operating at same steam pressure, is collected in a separator vessel. The condensate settles at the bottom of the separator vessel, and is removed with the help of a level control system.

The blow-through steam is directed to the thermocompressor, where it is compressed and then recirculated at a higher pressure, so it can be reused in the same dryer group. The thermocompressor also compresses steam from the flash vessel to a higher pressure for use in the process. This results in direct steam savings. Each group of cylinders is equipped with a fixed nozzle thermocompressor with an external equal percentage characteristic control valve specially designed for low pressure drop or minimum throttling conditions.

Further, the thermocompressor enhances condensate removal,effectively improving heat transfer conditions inside the dryer, and lowering steam consumption. The temperature profile also becomes more uniform as a result of effective condensate removal provided by the higher velocity steam injected by the thermocompressors. Quick condensate removal results in faster machines and improved productivity.

The thermocompressor operates under wide open conditions. Since the drier condensing load far exceeds the thermocompressor output, there is no operational difference between the fixed nozzle thermocompressor and the variable nozzle thermocompressor. It is only during sheet break or abnormal sheet conditions that the thermocompressor spindle is regulated to maintain differential pressure. At that point the differential pressure control valve begins venting blow thru to the condenser. An adequately high motive pressure would ensure that there is no loss of pressure to the fixed nozzle thermocompressor.

Cascade based blow through systems

Cascade based blow-through systems are suitable for high speed paper machines where high pressure motive steam is not required to be boosted for recovery. In this system,high pressure blow-through steam is recovered to a different thermal group that is operating at lower steam pressures. With this, 100% condensate evacuation is ensured and steam can also be utilised efficiently in the paper drying with the help of control loops.

Categories

Tags