Recovering condensate from the steam distribution network

Steam constantly loses heat due to radiation and condenses along the entire length of the steam distribution network. This condensate is separated out from steam through drain pockets on steam pipelines.

A typical steam network has many drain pockets with steam traps that intermittently discharge condensate. Although the quantity of condensate discharged at each such location in the distribution network may not be high, considering even a minimum distribution loss of 3% of plant steam generation, it is still commercially feasible to recover this condensate.

For example, the average distribution losses due to radiation and condensation for a plant generating about 100 tons/day of steam will be approximately 3 tons/day, that’s about 1,050 tons/year. Recovering this condensate can save the plant about 1,050 Kilolitres of water per annum in addition to fuel savings (21 tons of imported coal or 9.3 Kilolitres of furnace oil or 29 tons of biomass briquettes per year).

Typical concerns while recovering condensate from the steam distribution network

Two key factors discourage plants from recovering condensate from the distribution network: complexity in implementing the recovery network and high cost of implementation.

Complexity

Designing the mainline condensate recovery system is complex due to the following reasons:

- The sheer expanse of the distribution network and a large number of mainline steam traps which are spread out throughout the network which need to be connected in order to recover condensate.

- A separate condensate return header is necessary, as main line steam traps are at a high pressure, and cannot be connected to the process condensate return header which is generally at a lower pressure.

- Since the condensate discharge from a single mainline trap is typically low, it is necessary to collect condensate from multiple traps into a pump to enable effective recovery. This requires multiple condensate recovery pumps, clubbing traps connected to each pump and determining suitable pump

Cost

The high initial implementation costs, particularly related to piping expenses, acts as a deterrent for many plants considering the recovery of mainline condensate. However, it is important to note that the advantages of condensate recovery outweigh the initial costs, which may seem high. Additionally, right design can help reduce the overall cost of implementing an effective mainline condensate recovery system.

Designing a system to recover mainline condensate

While designing a system to recover condensate from the steam distribution network the following factors should be taken into consideration.

- Quantity of recoverable condensate

- Condensate pressure

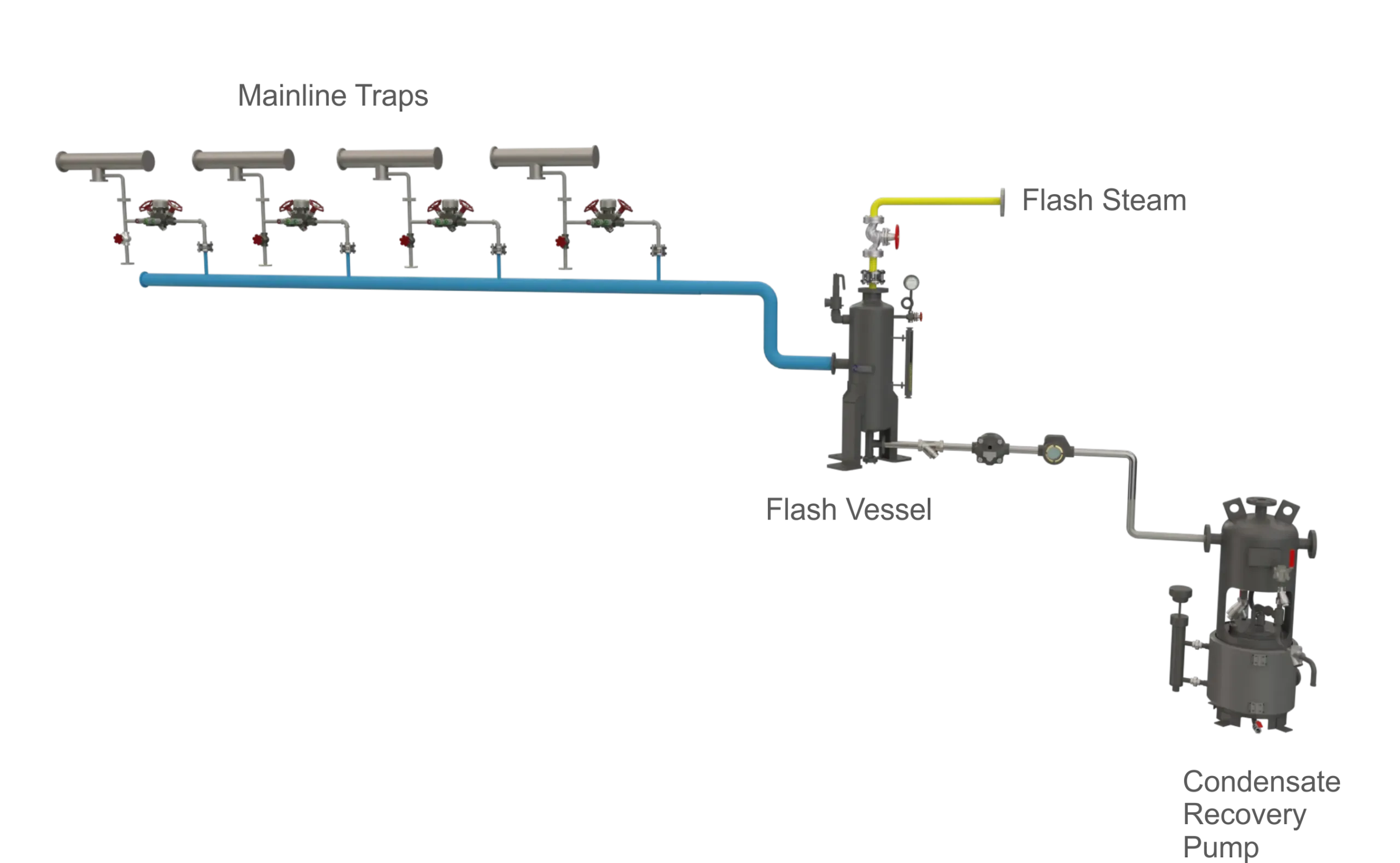

Ideally, the recovery system should be designed as per the schematic indicated below i.e. a set of steam traps in close proximity (at the same pressure) can be clubbed together and connected to a common flash vessel and condensate collection pump.

Illustration: Mainline Condensate Recovery