The need for steam traps

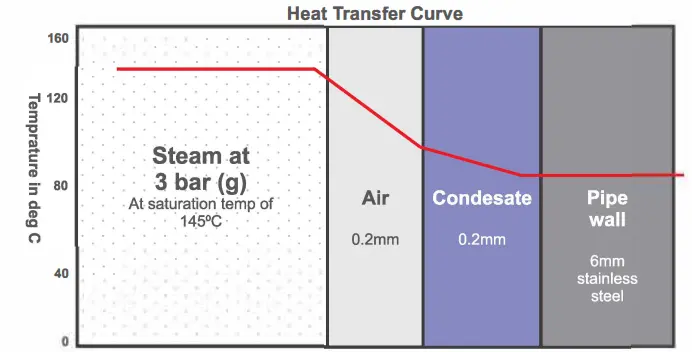

One of the challenges encountered in steam systems is the formation and accumulation of condensate in steam pipelines and equipment. If this condensate is not quickly evacuated from the pipelines and equipment, it impairs the efficiency of the system by obstructing the flow of steam, as well as impeding heat transfer, as it is a poor conductor of heat. The illustration below highlights the impact condensate has on heat transfer i.e. the temperature drop against just a 1 mm film of condensate is as high as 12.5°C.

Figure: Impact of condensate on heat transfer

Condensate accumulation within the steam pipelines also leads to the formation of wet steam and water hammer. Wet steam leads to increased steam demand to meet the process heat load. For example, 80% dry steam at 3barg has a heat content of 440Kcal/Kg whereas 98% dry steam at the same pressure has a heat content of 509Kcal/Kg. This difference in heat content between dry and wet steam leads to an increase in steam consumption. The figure below illustrates the phenomenon of water hammer caused due to the formation of a slug of condensate which has accumulated in the pipeline. As steam travels through the pipeline at 25 meters/ second (90 kilometers/hour) it pushes the slug of water at similar speeds. Water hammer occurs when such slugs of water traveling at high speeds collide against pipelines, accessories and process equipment heat transfer surfaces. Water hammer causes significant damage to pipelines, accessories and process equipment and impacts plant safety.

Video: Condensate accumulation leading to water hammer

Likewise, the build-up of condensate within process equipment, hampers effective heat transfer. As a result, either process temperatures do not reach desired levels, or there is a delay in attaining temperatures. This in turn, diminishes productivity and has adverse effects on product quality.

Condensate formation within pipelines and equipment varies. For example, in batch processes, condensation is higher at start up. Condensate loads can also vary due to other factors, for example due to changes in ambient temperatures, radiation losses can increase / decrease leading to variations in condensate formation in steam pipelines. Using manual valves to remove condensate is not practical because this would necessitate continuous adjustments to each valve based on changes in condensate load, to avoid steam loss or condensate build-up.

Steam traps were invented specifically to address this concern, enabling removal of, condensate automatically, without losing steam from pipelines and equipment, thereby addressing challenges posed to safety of plant and personnel, productivity, product quality and energy efficiency due to condensate accumulation. Over the years, various types of steam traps have been developed and refined to suit different applications.

Steam traps play a key role in ensuring the following

- Safety: Water hammer caused by condensate accumulation can create potentially dangerous situations by damaging steam pipelines and process equipment, leading to leaks or even catastrophic failures. Steam traps help mitigate these risks by preventing water hammer, thereby contributing to the safety of the system.

- Process Quality and Productivity: In processes that rely on steam for heating, the quality of steam is crucial. If condensate is allowed to accumulate and mix with steam, it negatively impacts heat transfer and the hence the quality of the process. Steam traps play a role in ensuring that only dry steam reaches the process equipment thereby maintaining product quality, consistency and productivity.

- Energy Efficiency: Steam traps help ensure dry steam is supplied to the process thereby reducing its energy consumption. Additionally, steam traps also enable the plant to implement a closed loop steam system i.e. recovery of condensate back to the boiler house.

- Equipment Protection: Condensate accumulation in the system leads to formation of wet steam, water hammer and corrosion, resulting in premature failure of process equipment, steam pipelines and accessories. Such failures are expensive both in terms of maintenance costs and production downtime. Right sizing, selection and installation of steam traps in the plant prevents condensate accumulation in the system thereby ensuring equipment uptime.

- Environmental Impact: By effectively evacuating condensate from the steam system and improving heat transfer efficiency, steam traps reduce the need to burn additional fuel, resulting in lower CO2 emissions.

In summary, steam traps are almost as important as the boiler within the steam system, as they ensure that steam is delivered and used effectively throughout the system.