Small leaks cost big money

A ⅛ inch hole in steam main can waste 9 tons of fuel oil per year. Small leaks cost big money, don’t ignore them.

Even insignificant looking steam leaks drain a significant amount of energy, thereby wasting fuel and money. Repair of steam leaks in the system are often not given timely attention.

Steam leaks, lead to a corrosive environment, and substantial monetary loss.. This causes a safety hazard to the plant personnel. Thus, it is essential to attend to them immediately.

A good operating practice would be that the plant operators or the designated authority survey the plant periodically to check for steam leaks. Once identified, the steam leaks should be repaired at the earliest to contain the losses.

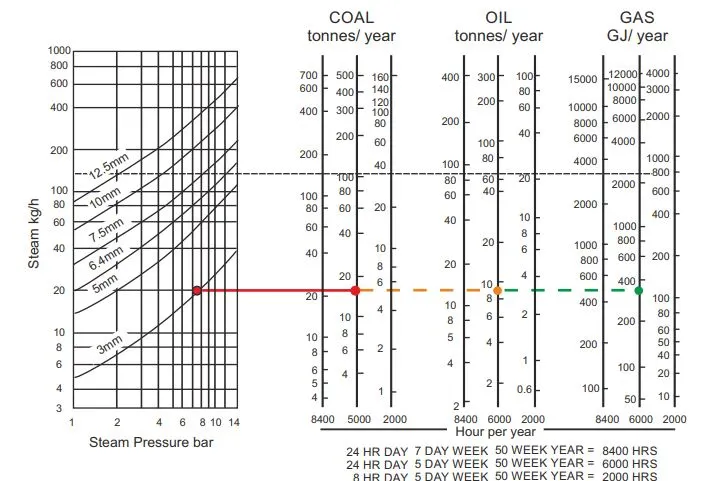

Illustration:

Considering 6000 hrs of annual operation, at 7 bar steam escaping through a ⅛ inch (or 3 mm) diameter hole wastes 15 tons of coal / 9 tons of oil annually.