Individual trapping lowers process time and reduces steam consumption.

Individual trapping of equipment lowers process time and reduces steam consumption. Hence, group trapping should be converted to individual trapping.

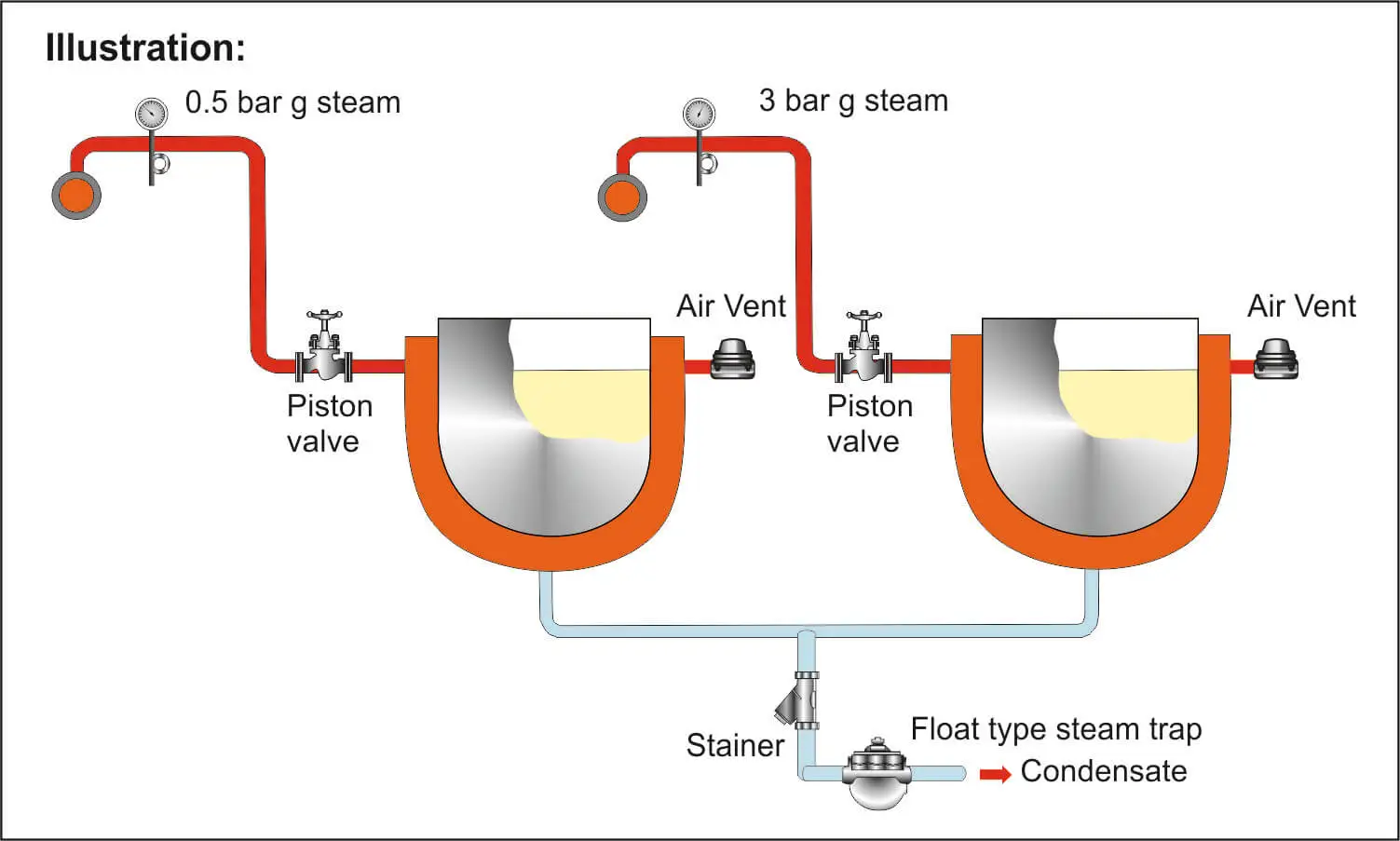

Group trapping is a condition in which one or more equipment / applications are connected to a single steam trap. This practice of grouping of batch equipment operating at different pressures is seen across many sectors of the industry.

In this case, the condensate from the equipment operating at higher pressure will drain but will stop condensate evacuation from the low pressure equipment. With the result the latter will water log and will suffer a drop in performance.

Inadequate condensate removal leads to higher heating times and thus higher steam consumption. It is recommended to provide individual trapping for equipment to ensure higher process efficiency with reduced steam consumption.