Condensate recovery using steam trap pressure

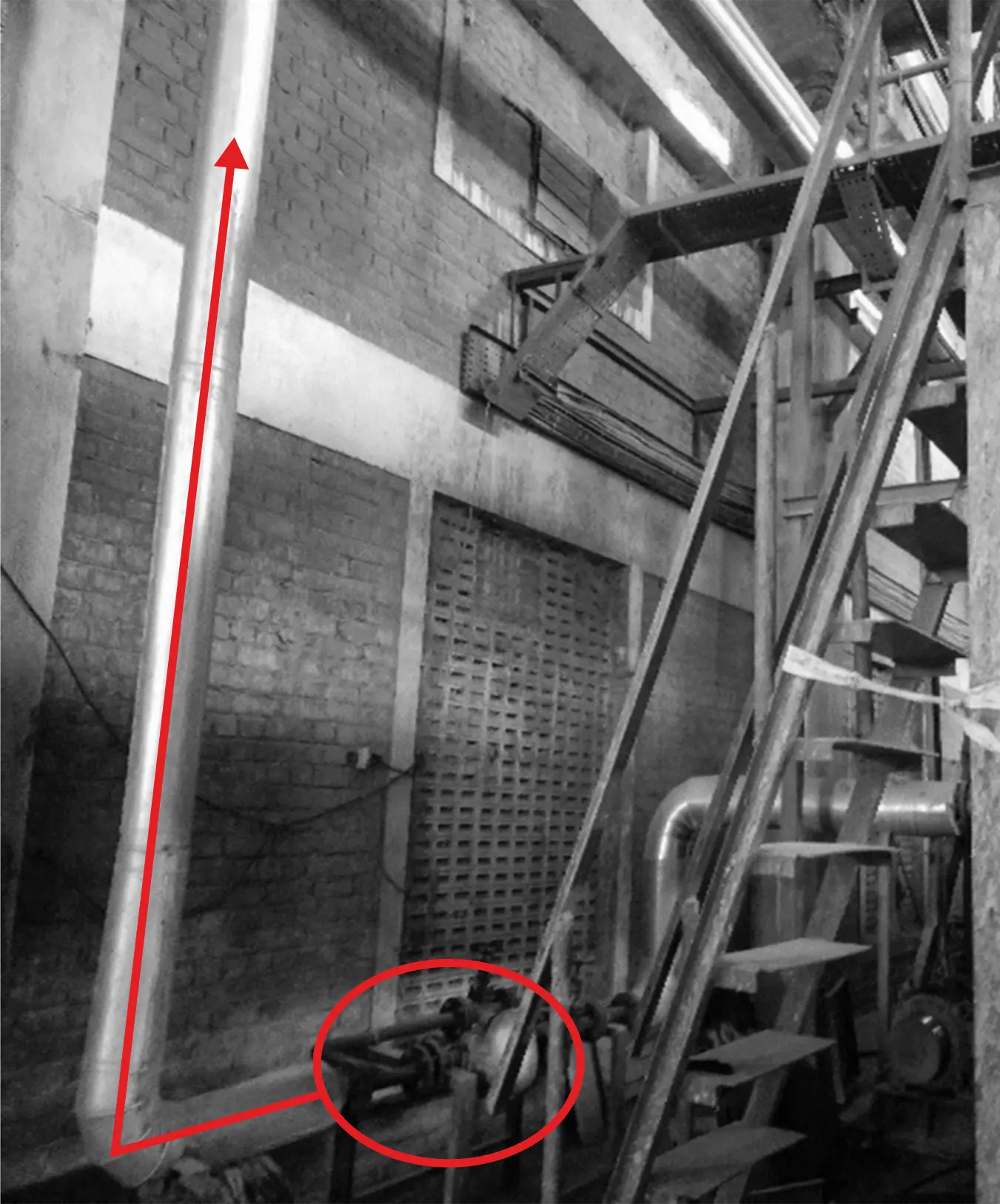

Recovering condensate by trap pressure is a common practice across many plants. The steam outlet after the trap is directly connected to the boiler feed water tank (see image below of a typical arrangement of condensate recovery by trap pressure from a process equipment).

The line after the steam trap is lifted vertically and connected to a common collection header and given the pressure in steam, it is expected that condensate will travel the distance from the equipment to the feed water tank without a pump.

Figure: Condensate recovery by trap pressure

Although, setting up this system is fairly simple from an implementation perspective, this design actually introduces various disadvantages that directly impact key performance indicators of the plant.

The condensate discharge capacity of a steam trap depends on the trap type, trap size and the differential pressure across the trap.

When the steam trap is used to return condensate to the feed water tank, it introduces a backpressure on the trap.

When the steam trap is used to return condensate to the feed water tank, it introduces a backpressure on the trap.

The backpressure is due to the distance the condensate has to travel, the presence of bends and elevations in the pipeline, and the connection of steam traps with different pressures in the same pipeline. As the backpressure increases, the differential pressure across the trap reduces. As a result, the condensate discharge capacity of the trap reduces, leading to insufficient condensate evacuation from the process equipment and diminished heat exchange.

The backpressure is due to the distance the condensate has to travel, the presence of bends and elevations in the pipeline, and the connection of steam traps with different pressures in the same pipeline.

As the backpressure increases, the differential pressure across the trap reduces. As a result, the condensate discharge capacity of the trap reduces, leading to insufficient condensate evacuation from the process equipment and diminished heat exchange.

Disadvantages of recovering condensate by trap pressure

- Lower Productivity – Condensate evacuation from the process equipment is hampered. This can result in equipment productivity issues due to longer startup times and extended heating times (batch times).

- Rejections / Reprocessing – Due to higher back pressure on the steam trap condensate accumulates in the process equipment and required process parameters such as temperature and temperature gradients cannot be achieved. This can impact product quality leading to rejections or necessitating reprocessing.

- Loss of energy – Steam traps are frequently bypassed in order to fulfill process requirements resulting in steam loss.

- Unsafe – Condensate accumulation in the process equipment can cause water hammer, damaging the process equipment and resulting in steam leaks