Pasteuriser

Pasteurisation or UHT ensures food safety by killing harmful pathogens and extends the shelf life of perishable products. Operational concerns across plants includes challenges in achieving the desired time-temperature profile, lower productivity, higher steam consumption, poor condensate recovery and frequent damage to heat exchangers.

Deviations in pasteurisation / UHT temperatures are caused due to conventional steam control methods, unnecessarily high steam pressure and condensate accumulation in the heat exchangers. Inconsistent temperature activates the flow diversion valve, reducing productivity. As the diverted product needs to be reprocessed, it increases both heating and chilling loads. This leads to more energy use and higher conversion costs.

Condensate build-up in the heat exchangers due to stall, not only hinders heat transfer but also leads to water hammer, causing frequent damage and heat exchanger downtimes.

Our Solution:

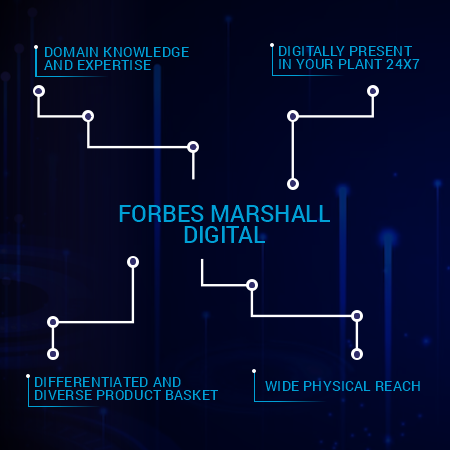

Forbes Marshall provides a complete solution designed to optimise