Resolving PET Line Temperature Challenges with a Tailored Condensate Recovery Solution

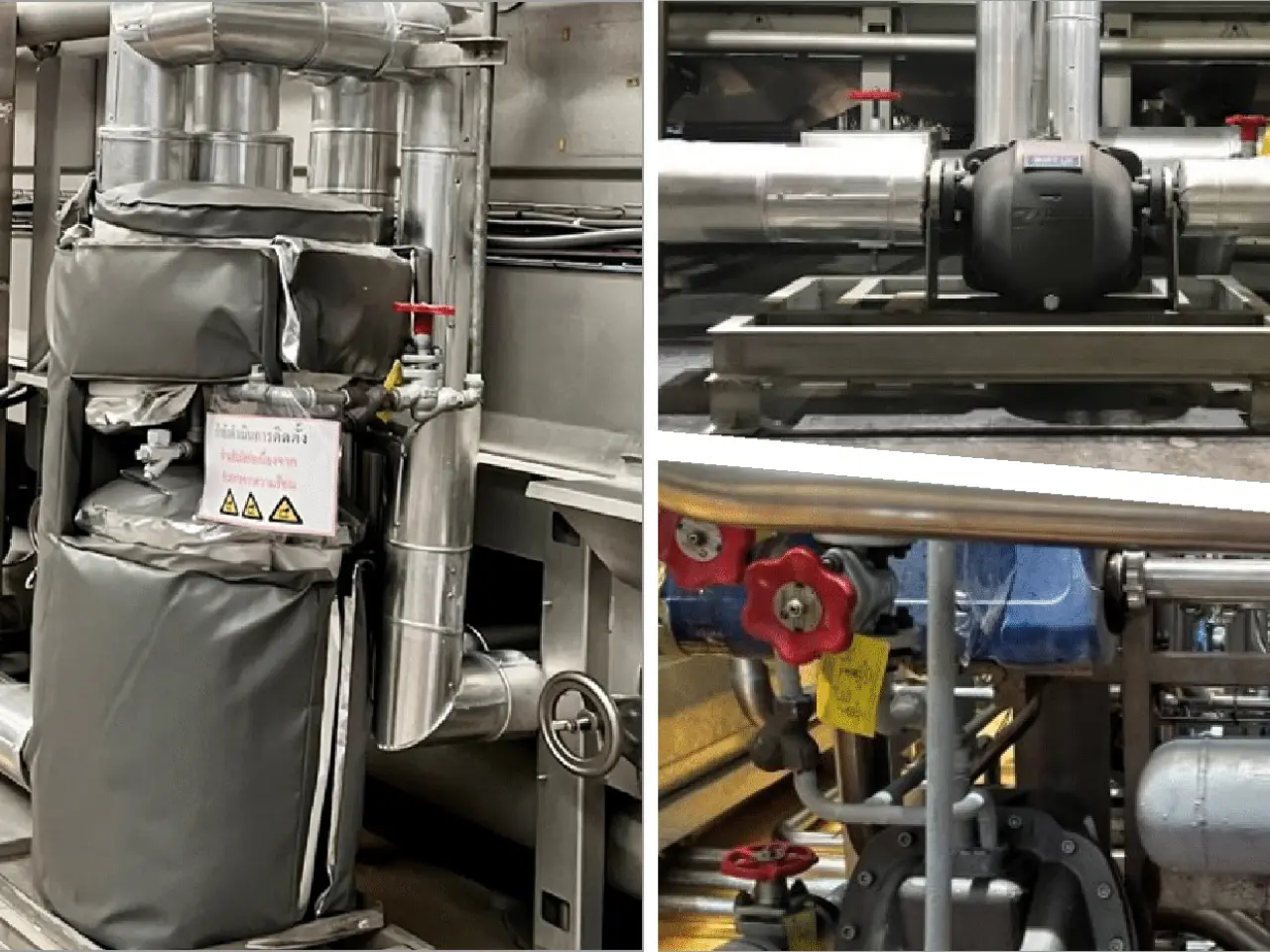

The plant was struggling to achieve the required temperature in the PET line Warmer, Forbes Marshall engineers conducted a thorough evaluation. We observed that the steam trap outlet temperature was only 50°C, indicating stalling in the heat exchanger. This was caused by incorrect steam trap selection and a 15-metre lift in the condensate line after the trap. The Condensate Recovery System (CRS) was also compromised, leading to further inefficiencies.

We implemented a holistic solution that addressed these problems. This involved selecting a steam-operated pump trap, eliminating the lift in the condensate line, and using a steam-powered pump to transfer condensate to the boiler feed water tank. These measures resolved the temperature issues in the warmer, improving its overall efficiency and enabling the plant to recover 100% of the condensate from the equipment.

What to read next

Products

Associated Services

Process Optimization

Improving Uptime