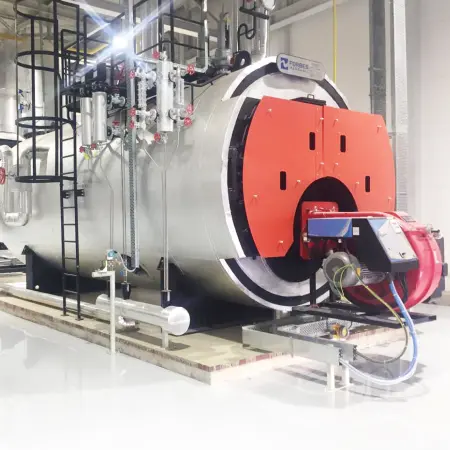

Steam consumption per batch of platten presses often varies by 20-30%, resulting in increased costs.

In today’s dynamic and competitive landscape, where energy costs continue to rise, maintaining an efficient steam system is imperative. An increase in specific steam consumption (SSC) per batch and a drop in condensate recovery factor (CRF) leads to incremental fuel and fresh water consumption.

SSC and CRF variation causes include:

- Design of the steam condensate system,

- Uptime of components and control loops,

- Operating pressures and temperature set-points

- Operating procedures

- Ply / laminate quality and type

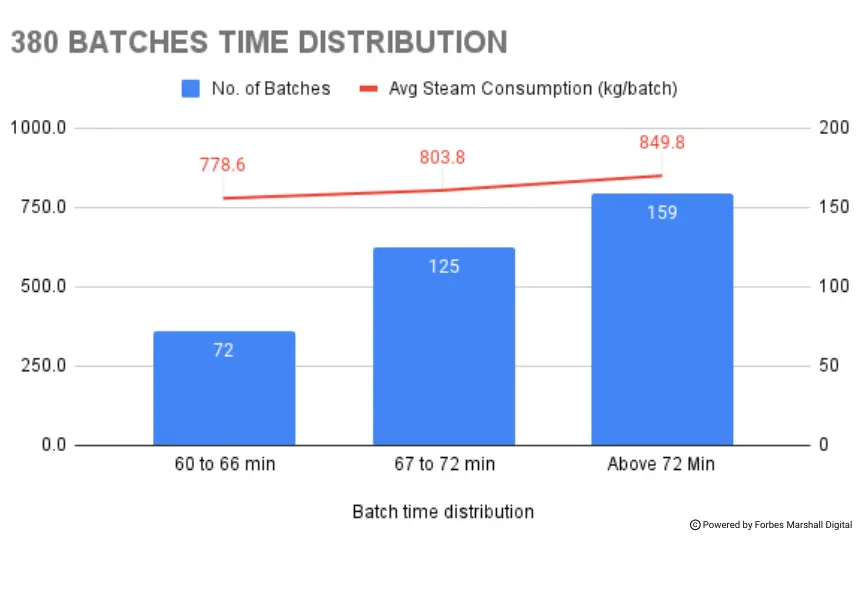

- Batch time

- Operator experience

Key parameters we monitor

Steam consumption per batch

Condensate recovery factor

Operating steam pressures

Platten and CBT temperature

Batch time and cycle time for each batch

Heating and cooling temperatures

Uptime of individual instruments and accessories

We provide actionable insights

Delivering Benefits

Our

footprint

Our footprint across services

0

Plants

0

Assets

0

Parameters