Selection

Thermodynamic steam traps are considered to be the best choice for evacuation of condensate from the steam distribution pipelines.

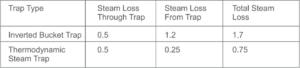

Thermodynamic steam traps have several advantages over mechanical and thermostatic steam traps. For example, the OPEX for Thermodynamic steam traps is

significantly lower vis-a-vis Inverted Bucket steam traps installed on mainlines as illustrated in the table below.

The steam loss through and from the steam trap as per the International Standard ISO7841 (1988) and European Standard CEN27841 (1991) is indicated below :

Our own experience across thousands of plants indicates that there is a significant benefit in terms of opex by installing thermodynamic steam traps instead of inverted bucket steam traps.

The data in the table below from a process plant highlights the impact of using thermodynamic steam traps versus inverted bucket steam traps on main lines.

The higher temperature by 3°C and the higher condensate load by 0.934 kilograms/hour in case of the inverted bucket trap is on account of the higher steam loss through and from the trap. Annually this amounts to 7,845 kilograms (7.8Tons) of steam loss from a single trap. Given that most plants have upwards of 50 mainline steam traps this loss can amount to about 392,280 kilograms of steam annually.

The higher temperature by 3°C and the higher condensate load by 0.934 kilograms/hour in case of the inverted bucket trap is on account of the higher steam loss through and from the trap. Annually this amounts to 7,845 kilograms (7.8Tons) of steam loss from a single trap. Given that most plants have upwards of 50 mainline steam traps this loss can amount to about 392,280 kilograms of steam annually.

Thermodynamic steam traps also have several other advantages. They are suitable for both high and low pressure systems. They are highly resistant to damage due to

water hammer, which is important, considering that even in a well-designed network, water hammer can sometimes occur. In some areas prone to sub-zero temperatures, freezing can also cause problems, particularly for lines exposed to the environment. In such cases too thermodynamic steam traps are recommended since they are resistant to freezing. Thermodynamic steam traps are very easy to maintain, offering a long service life. A mainline steam trapping station should have an inlet isolation and outlet isolation valve, a strainer, a trap bypass valve, a trap depressurization valve and a trap test valve. In a conventional steam trapping station, all of these individual accessories are connected together with piping to build the station making it not only] cumbersome to install but also difficult to maintain.

Advancements in thermodynamic steam trapping solutions

State-of-the-art thermodynamic steam traps encompass the complete steam trap module in one single forged body. These solutions are easy to install, operate and

maintain and offer several advantages over a conventional steam trapping station.

Conventional Steam Trapping Station

- Approximately 750milimeters assembly length and weighing over 14 kilograms (30 pounds)

- Has 16 components with 5 valves requiring on-site fabrication and welding (15 weld joints); ~ 4 hours to install and commission

- Shutdown / safe isolation not possible, hampering online / in-line maintenance as traditional valves are prone to leakages and seizing up

- The disc can be replaced but the trap needs to be replaced in case of damage to the seat

- Cumbersome to maintain due to welded joints

- Potential steam leaks through inline leakages, glands and weld joints

Advanced Mainline Steam Trapping Solution

- Compact and lightweight – 190milimeters assembly length and weighing about 6 kilograms (13 pounds)

- Only one component with 5 integral piston valves; installation time of ~30 minutes

- Integral bypass valves and class VI isolation valves enabling easy and safe online/ in-line maintenance

- Replaceable seat and disc

- Quick and easy to maintain