How can industries scale operations sustainably through digital solutions, going #BeyondConnectivity?

In today’s rapidly evolving industrial landscape, the push for sustainability has become increasingly critical. As global pressures mount to reduce environmental impact and enhance operational efficiency, industries must leverage innovative methods to scale their sustainability efforts. This is where digital transformation comes into play. By integrating advanced digital technologies, industries can achieve significant improvements in resource management, energy efficiency, and overall sustainability.

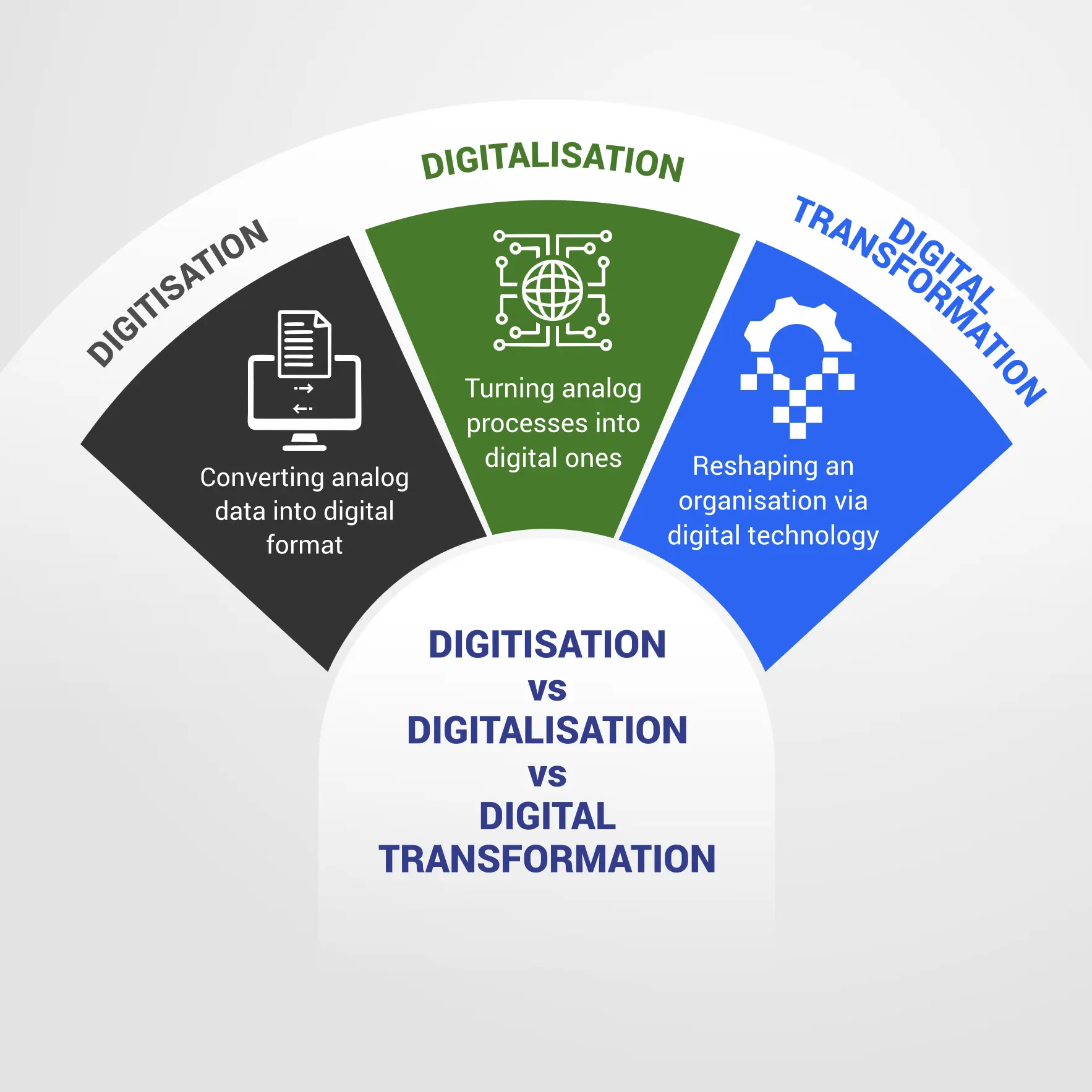

What is digital transformation and why are we #BeyondConnectivity

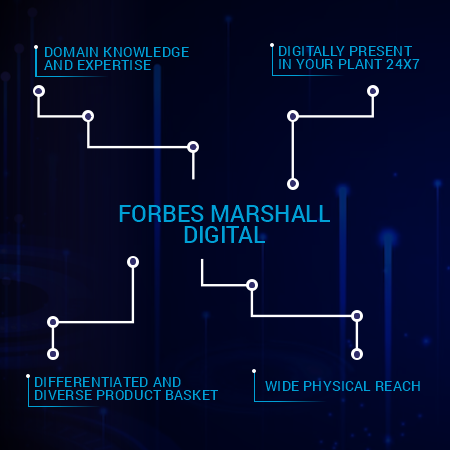

Digital, digitalisation, digital transformation and digital solutions have become buzzwords in industry recently. Each of us, at some point in time, have been on the receiving end of a “data dump” – and beginning to tackle it feels like a task. We, at Forbes Marshall, do not just want to help digitise key impact areas of your plant. Instead of only equipping you with intuitive data dashboards, our specialists analyse real-time plant data and provide actionable insights such that immediate corrective actions can be taken by plant personnel. Depending on the issue raised, we visit your plant and provide on-site support, ensuring safety and reducing downtime. All our EverSense digital solutions work seamlessly with over 70% of our differentiated and diverse product basket providing insights into aspects ranging from steam engineering to control instrumentation

Why digital transformation is key to industrial sustainability

Digital transformation has become a necessity for industries looking to thrive in a competitive and environmentally conscious world. This allows industries to enhance resource management and make data-driven decisions, improving productivity and staying in compliance with regulatory norms. By partnering with Forbes Marshall Digital, we together go #BeyondConnectivity and help ensure smooth and efficient operations. Our data-driven actionable insight ensures corrective action can be taken immediately, reducing the potential impact on productivity, correcting operating practices which impact uptime of the equipment, while increasing safety.

Sustainability through #BeyondConnectivity

Our dedicated team of engineers provide continuous remote monitoring with monthly reports having actionable insights to better your process. This ranges from tracking energy consumption to immediately flagging equipment deviations which can impact batch times and production quality. Lowering fuel, water and/ or compressed air consumption lessens one’s carbon footprint. The data also indicates health of the equipment, ensuring planning for spares and other corrective actions – keeping uptime at a benchmark level. This ensures productivity and the quality of production is maintained, while keeping costs controlled, resulting in the potential to scale the business.

To know more about Forbes Marshall Digital and its solutions, explore here.